Bracket ea Metal Sheet e Tloaelehileng e nang le Precision CNC Machining libaka libakeng tse 'maloa

Ho HY Metals, re motlotlo ka ronaLilemo tse 14 tsa boiphihlelole boitlamo ba ho fana ka boleng bo phahameng ka ho fetisisaho etsa moetlotharollo. Boitseanape ba rona bo hoho nepahala letlapa la tšepeboiqapeloleMechine ea CNC, 'me re ikemiselitse ho fa bareki ba rona lihlahisoa tse holimo ka ho fetisisa tse finyellang litlhaloso tsa bona tse nepahetseng.

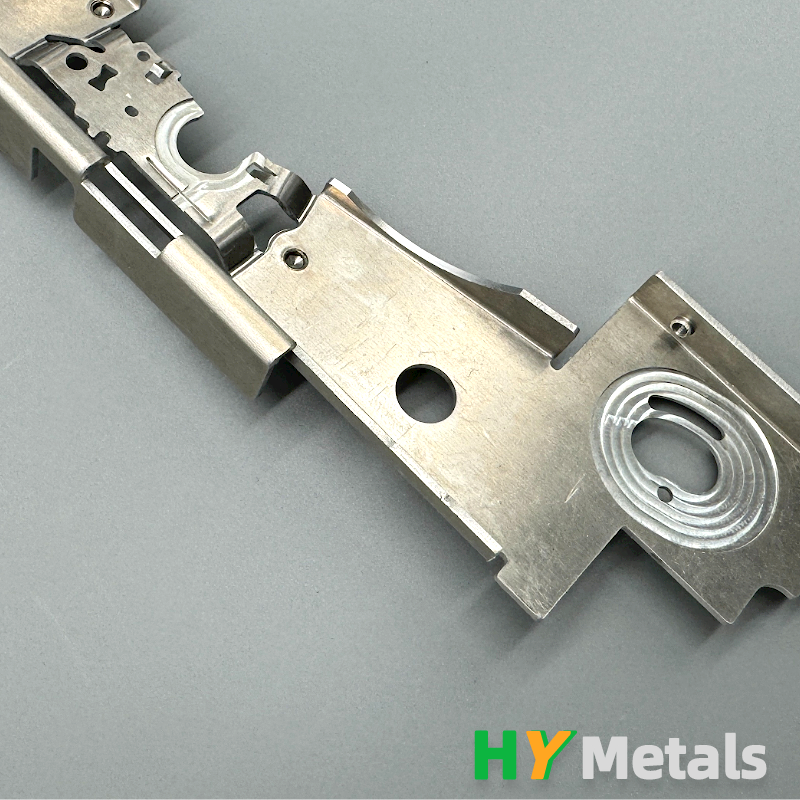

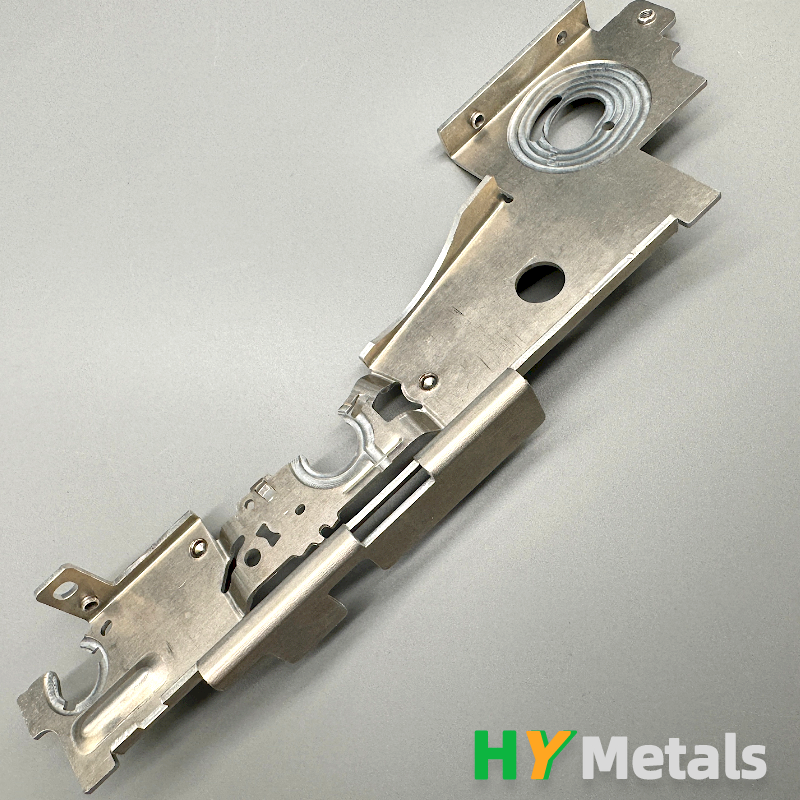

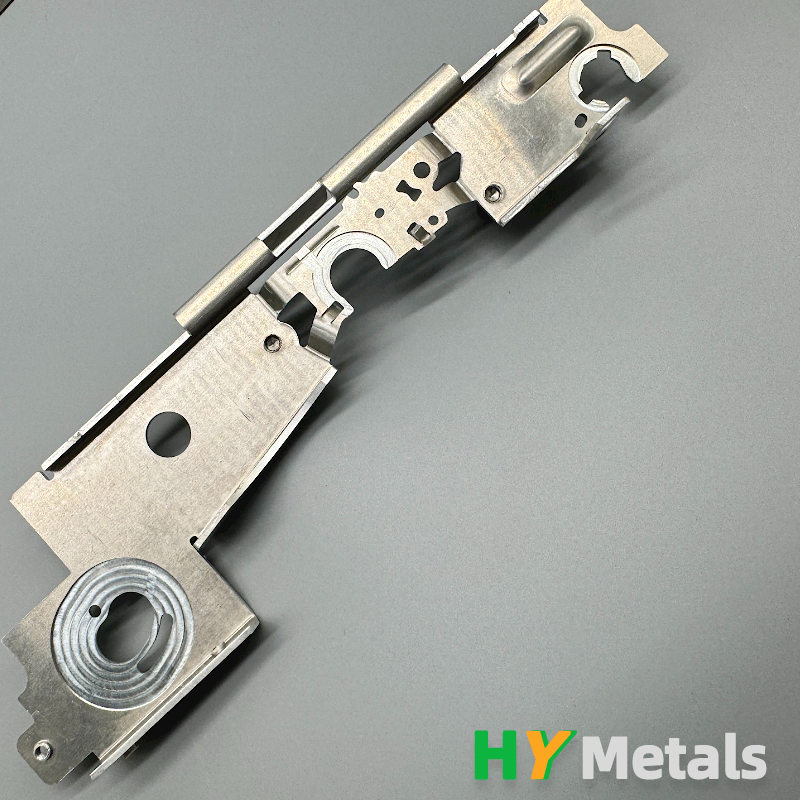

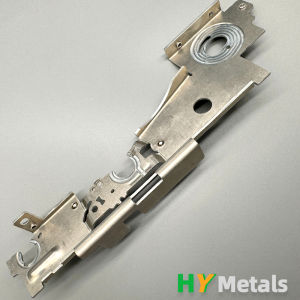

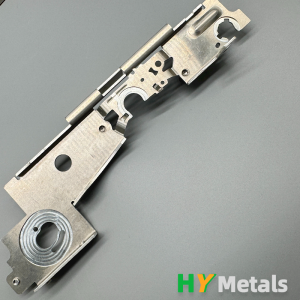

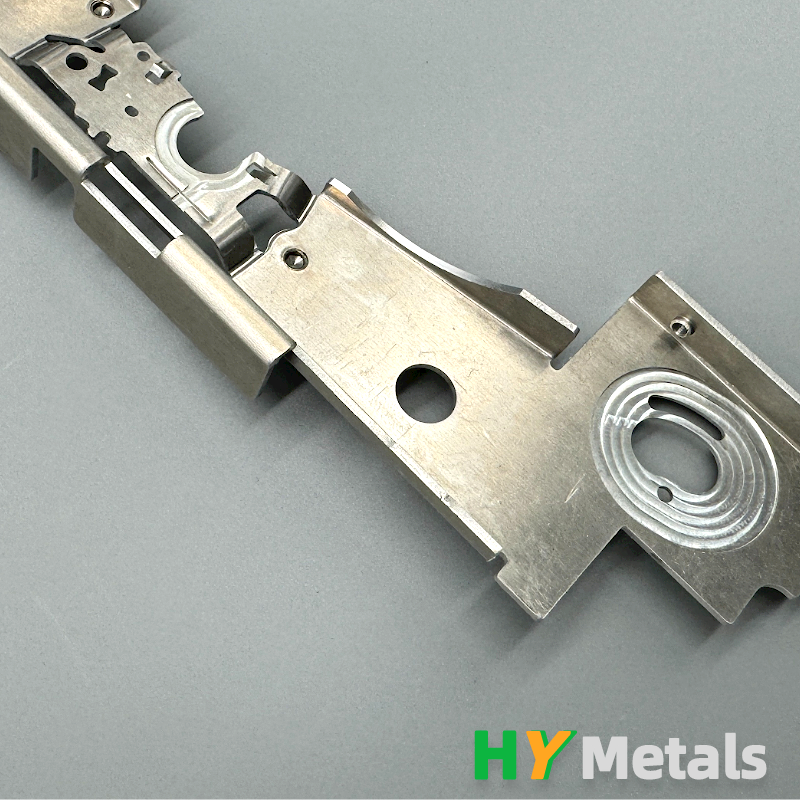

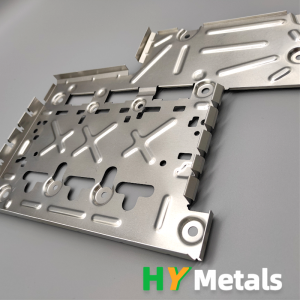

Morero oa morao-rao o bontšang bokhoni ba rona o kenyelelitse tlhahiso ealikarolo tsa tšepe tse tloaelehilengentsoe ka Al5052 bakeng samasakana a likoloi. Li-brackets li etsa letoto la lits'ebetso tse kenyelletsang ho itšeha ka laser, ho kobeha le ho riveting, pele li hloka machining a nepahetseng libakeng tse 'ne tse ikhethileng ho theha li-circles. Ts'ebetso ena e bohlokoa ho ikamahanya le likarolo tsa elektronike mothating o latelang oa kopano.

Phephetso ea ho boloka mamello ea machining ka mor'a ho khumama ke bothata bo tloaelehileng indastering ea tšepe. Ho fapana le machining a CNC, mamello ea likarolo tsa tšepe ha e thata haholo, 'me ka mor'a ho kobeha, ho thata ho boloka karolo mochining oa CNC bakeng sa boemo bo nepahetseng. Leha ho le joalo, ho HY Metals, re na le boiphihlelo le theknoloji ea ho hlola mathata ana le ho fumana liphetho tse holimo.

Ho boloka likarolo tsa tšepe mochining oa CNC ho ka ba phephetso, empa ho na le mekhoa le lintlha tse 'maloa tse ka thusang ho netefatsa mamello e tiileng ea machining.

1. E tlamelle ka nepo: Sebelisa li-clamp, li-vises, kapa lisebelisoa tse tloaelehileng ho tšoaralikarolo tsa tšepesebakeng se sireletsehileng. Ha o rala sesebelisoa, nahana ka botenya ba thepa, sebopeho, le deformation e ka bang teng nakong ea ts'ebetso.

2. Mehlahare e Bonolo:Haeba u sebelisa vise, nahana ka ho sebelisa mehlahare e bonolo ho thibela tšenyo kapa ho senyeha ha lesela la tšepe. Mehlahare e bonolo e ka etsoa ka mochini ho tsamaisana le li-contours tsa karolo, ho fana ka tšehetso e betere le ho fokotsa ho thothomela.

3. Mehaho ea tšehetso:Bakeng sa likarolo tse kholo kapa tse rarahaneng tsa lakane, nahana ka ho sebelisa meaho ea ts'ehetso kapa lisebelisoa tse ling ho fokotsa ho kheloha nakong ea machining.

4. Lintlha tsa litšupiso:Theha lintlha tse hlakileng tsa litšupiso holim'a likarolo tsa tšepe ho netefatsa boemo bo tsitsitseng le ho lumellana nakong ea ts'ebetso. Sena ke sa bohlokoa ho boloka mamello e tiileng.

5. Leano la ho koala:Theha leano la clamping le arolang ka ho lekana matla a clamping holim'a karolo ho fokotsa deformation. Nahana ka ho sebelisa li-clamp tsa boemo bo tlase kapa li-clamps ho qoba ho kena-kenana le lisebelisoa tsa ho itšeha.

6. Ntlafatso ea tsela ea lisebelisoa:Sebelisa software ea CAM ho hlahisa litsela tsa lisebelisoa tse fokotsang ho thothomela le ho kheloha ha lisebelisoa, haholo ha ho etsoa likarolo tse tšesaane kapa tse bonojoana tsa tšepe.

7. Tlhahlobo le maikutlo:Kenya ts'ebetso ea tlhahlobo e matla ho netefatsa ho nepahala ha litšobotsi tsa mochini. Sebelisa maikutlo a tsoang ho liphetho tsa tlhahlobo ho ntlafatsa litlhophiso le maano a mochini bakeng sa tlhahiso ea nako e tlang.

Ka ho rarolla mathata ana, bahlahisi ba ka ntlafatsa ho nepahala le ho tsitsa haCNC machining ea likarolo tsa tšepe tsa lakane, qetellong ea netefatsamamello e thata lia fihleloa.

Ka sehlopha sa basebetsi ba fetang 350 ba koetlisitsoeng hantle le meaho ea morao-rao e nang le mechini e fetang 500., re khona ho sebetsana le merero ea boholo leha e le bofe. Ebang ke prototype e le 'ngoe kapa letoto la tlhahiso ea likete, re ikemiselitse ho fana ka likarolo tsa boleng bo holimo ho liindasteri tse fapaneng.

Boitlamo ba rona ba bokhabane le ho ela hloko lintlha ka botlalo bo bonts'oa ts'ebetsong e atlehileng ea projeke ea hau ea borakete ea koloi. Ho sa tsotellehe ho rarahana ha mokhoa oa ho koala ka morao, re etsa bonnete ba hore li-brackets tsa tšepe tse phethiloeng li finyella litekanyetso tse phahameng ka ho fetisisa tsa ho nepahala le boleng.

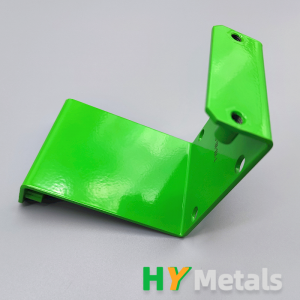

Ha u khetha HY Metals bakeng sa litlhoko tsa hau tsa tlhahiso ea tloaelo, u ka lebella:

1. Tlhahiso ea tšepe e nepahetseng ea lakane le tsebo ea ho sebetsa ea CNC

2. Sehlopha se inehetseng se ikemiselitseng ho fana ka lihlahisoa tsa boleng

3. Bokhoni ba ho sebetsana le merero ea boholo leha e le bofe, ho tloha ho prototyping ho ea ho tlhahiso ea bongata

4. Ho ela hloko lintlha tse qaqileng le boinehelo ba ho finyella litlhoko tsa hau hantle

Hore na o hlokaho nepahala lakane likarolo tsa tšepe, prototypes tšepe sheet, ho sebetsa ka nepo or litharollo tsa tlhahiso ea moetlo, HY Metals ke molekane oa hau eo u mo tšepang. Ikopanye le rona kajeno ho buisana ka litlhoko tsa projeke ea hau le ho utloa phapang eo boiphihlelo le boinehelo ba rona bo e etsang ho fana ka liphetho tse ikhethang.