Ts'ebeletso ena hangata e sebelisoa ho theha meaho, likarolo le likarolo bakeng sa liindasteri tse fapaneng, ho kenyeletsoa likoloi, sebaka sa sefofane, bongaka le kaho. Sheet tšepe tjheseletsa le kopano e ka sebelisoa ho etsa lihlahisoa tsa boholo leha e le efe le ho rarahana. Litsebi tse sebetsanang le mosebetsi ona oa matsoho ka ho khetheha li sebelisa lisebelisoa le mekhoa ea ho cheseletsa ea boleng bo holimo ho etsa bonnete ba hore ho na le tjheseletso e matla, e tšoarellang e finyellang litlhoko tsa moreki. Ba boetse ba nahanela mofuta oa tšepe e sebelisoang le tikoloho eo sehlahisoa se tla sebelisoa ho eona.

Mekhoa ea ho Etsa Metal Sheet:Ho poma,Ho khumama kapa ho theha, Ho tlanyakapaHo tsubella,Welding leKopano.

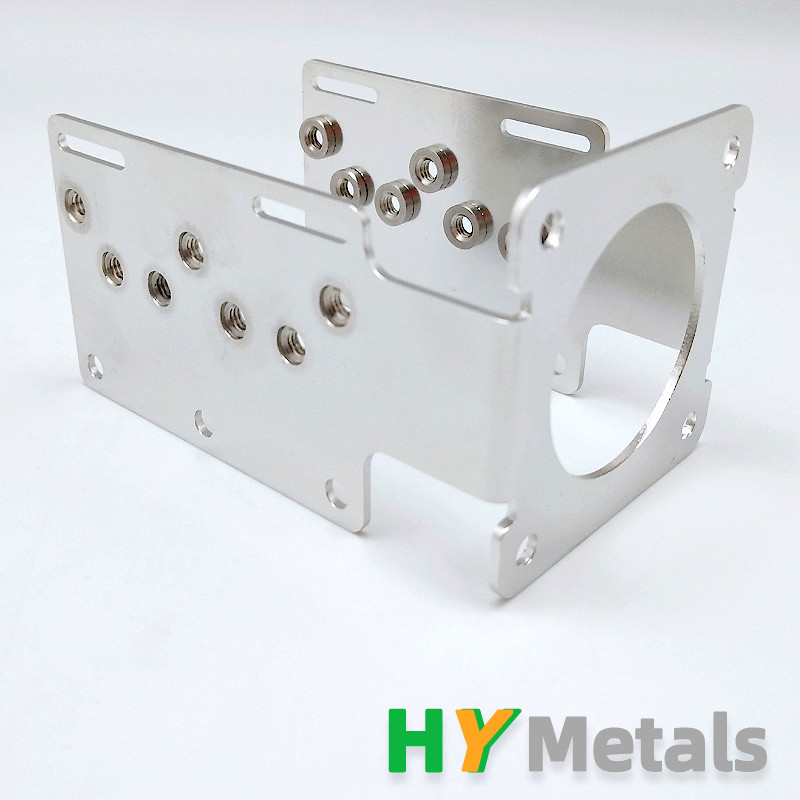

Kopano ea tšepe ea pampiri ke ts'ebetso ka mor'a ho itšeha le ho khumama, ka linako tse ling ke ka mor'a mokhoa oa ho roala. Re atisa ho kopanya likarolo ka ho riveting, welding, ho tobetsa fit le ho tlanya ho li kopanya hammoho.

Ho tlanya le ho Riveting

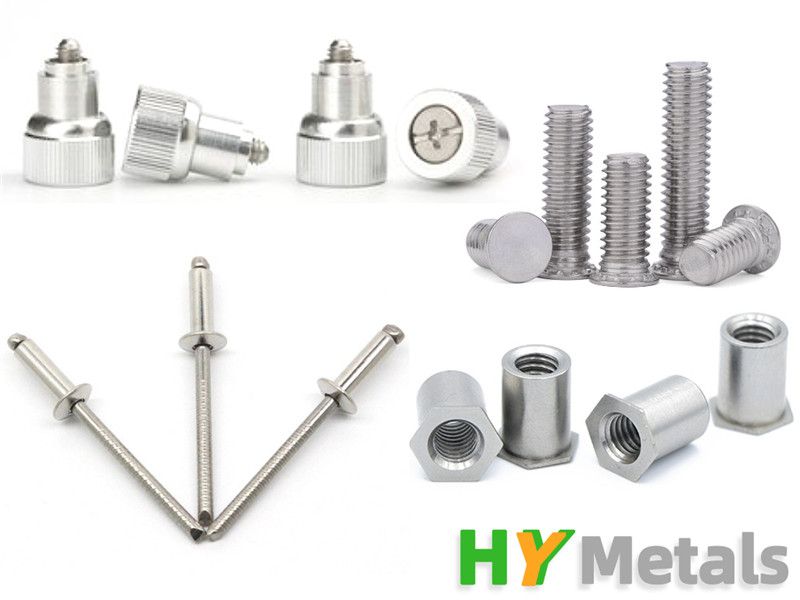

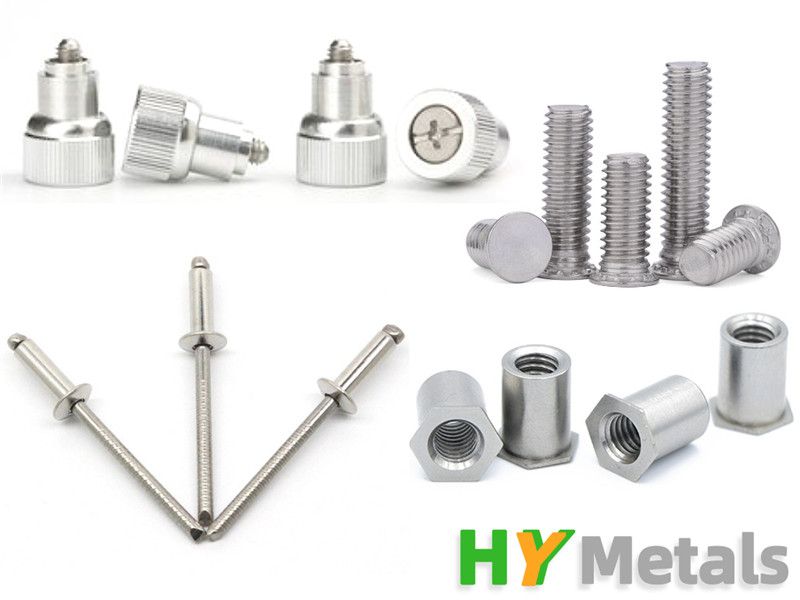

Likhoele li phetha karolo ea bohlokoa likopanong. Ho na le mekhoa e 3 ea mantlha ea ho fumana likhoele: Ho tlanya, ho riveting, ho kenya likhoele.

1.Tapping likhoele

Ho tlanya ke mokhoa oa ho etsa likhoele ka mekoting ea likarolo tsa tšepe kapa likarolo tse entsoeng ka mochini oa CNC ka mochini oa pompo le lisebelisoa tsa ho tlanya. E sebelisoa haholo linthong tse ling tse teteaneng le tse thata tse kang tšepe le likarolo tsa tšepe.

Bakeng sa lisebelisoa tse tšesaane tsa tšepe kapa tse bonolo tse kang aluminium le likarolo tsa polasetiki, li-riveting le ho kenya li-coil li tla sebetsa betere.

2.Rho hloloheloa Nuts le Standoffs

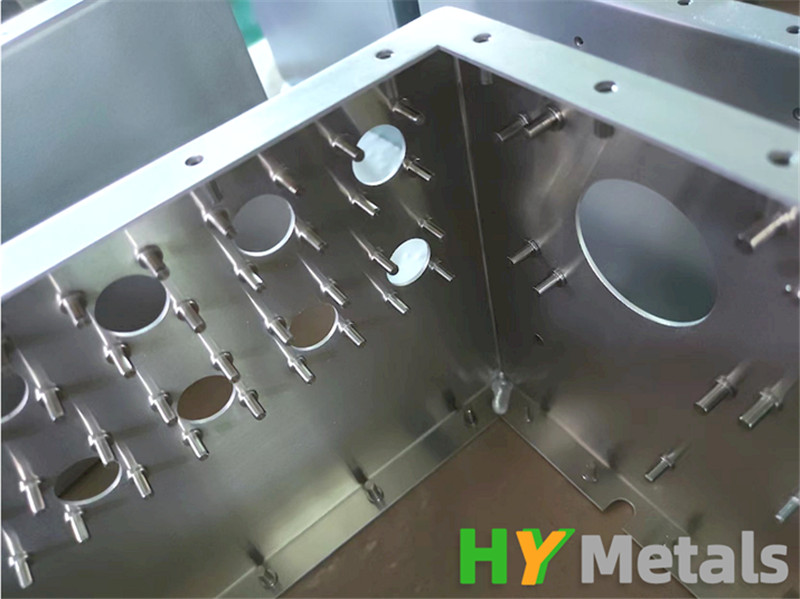

Riveting ke mokhoa o bonolo ka ho fetesisa o sebelisoang haholo oa ho kopanya lipampiri tsa tšepe.

Riveting e ka fana ka likhoele tse telele le tse matla ho feta ho tlanya poleiti ea tšepe e tšesaane

Ho na le linate tse ngata, li-screws le li-standoffs bakeng sa riveting. U ka fumana lisebelisoa tsohle tse tloaelehileng tsa PEM le lisebelisoa tse ling tsa MacMaster-Carr ho tsoa ho HY Metals bakeng sa kopano ea hau.

Bakeng sa lisebelisoa tse khethehileng tseo re ke keng ra li fumana mabenkeleng a lehae, u ka re fa tsona bakeng sa ho li kopanya.

3. Ho kenya Heli-coil kenya

Bakeng sa lisebelisoa tse ling tse teteaneng empa tse bonolo joalo ka likarolo tse entsoeng ka polasetiki, hangata re kenya lintho tse kenyang Heli-coil ka mekoting e entsoeng ka mochini ho fumana likhoele tsa ho kopanya.

Tobetsa Fit

Tobetsa e loketse bakeng sa lithakhisa tse ling le kopano ea shaft, 'me e sebelisoa haholo likarolong tse entsoeng ka mechine, ka linako tse ling e hlokahalang mererong ea tšepe ea sheet.

Welding

Welding ke mokhoa o mong o sebelisoang hangata oa ho kopanya ha ho etsoa masela a tšepe. Welding e ka etsa hore likarolo tse 'maloa li kopane hammoho ka matla.

HY Metals e ka etsa welding ea laser, welding ea Argon-arc le Carbon dioxide arc welding.

Ho ea ka ts'ebetso ea ts'ebetso ea tšepe ea tšepe, e arotsoe ka ho tjheseletsa letheba, ho tjheseletsa ka ho feletseng, ho tiisa metsi.

Re ka fihlela litlhoko tsohle tsa hau mabapi le tjheseletso ea tšepe bakeng sa likopano tsa hau.

Ka linako tse ling, re tla bentša matšoao a welding ho fumana sebaka se boreleli pele re roala.