Litšebeletso tsa machining tsa CNC tse phahameng ka ho fetesisa tsa PEEK likarolo tsa mochini

Ka tlhahiso, ho nepahalaLikarolo tsa mochini oa CNCli bohlokoa bakeng sa mefuta e fapaneng ea lihlahisoa le lits'ebetso. Ho tlohakoloilesefofaneho tsa bongaka le tsa elektroniki, tlhokahalo ea boleng bo holimolikarolo tse entsoeng ka mochini oa CNCe tsoela pele ho hola. Joalo ka morekisi ea etelletseng pele indastering, HY Metals e ikemiselitse ho fana ka likarolo tsa mochini tsa CNC tse maemong a holimo, ho kenyeletsoa.Karolo ea polasetiki e entsoeng ka mochini oa CNCs lePEKElikarolo tse entsoeng ka mochine, ka ho toboketsaho nepahala ho hodimolephetoho e kgutshwane.

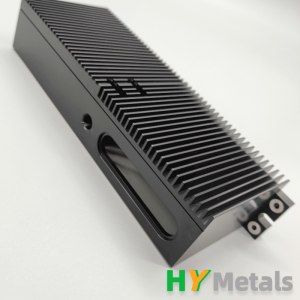

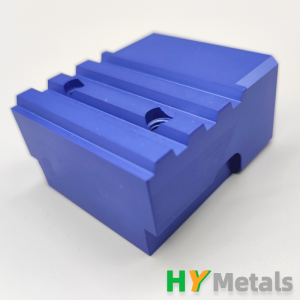

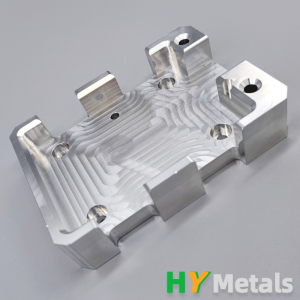

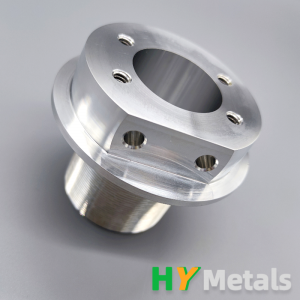

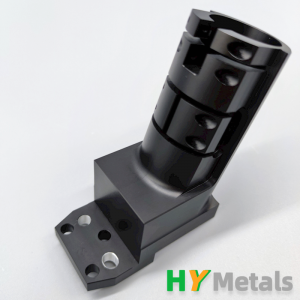

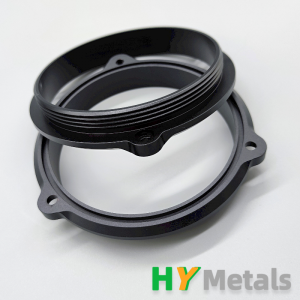

HY Metals e na le 4 ea boemo bo holimoLithupelo tsa mochini oa CNCe nang le lisebelisoa tse fetang 150 tsa mochini oa CNC le likhoele tse fetang 80. Ka basebetsi ba nang le litsebo ba 120 le sehlopha se matla sa boenjiniere le taolo ea boleng, re khona ho hlahisa likarolo tse entsoeng ka mokhoa o phahameng oa CNC ka nako ea ho fana ka nako e potlakileng. Tsebo ea rona ea ho sebetsana le thepa e kang aluminium, tšepe, tšepe ea lisebelisoa, tšepe e sa hloekang le lipolasetiki tse fapaneng tsa boenjiniere tse kenyeletsang PEEK, ABS, Nylon, POM, Acrylic, PC le PEI e re nolofalletsa ho finyella litlhoko tse sa tšoaneng tsa bareki.

Ha ho tluoa tabeng ea lisebelisoa tsa ho sebetsa, re utloisisa litšobotsi tse ikhethang le liphephetso tsa thepa ka 'ngoe. Ka mohlala, aluminium e batla e le bonolo ho e etsa mochine, ha tšepe e sa hloekang e hlahisa mathata a mangata ka lebaka la ho thatafala ha eona. Leha ho le joalo, ho HY Metals re na le bokhoni ba ho hlola mathata ana le ho netefatsa horelikarolo tsohle li entsoe ka nepo ho kopana le mamello e hlokahalang ea ho taka. Re boetse re na le boiphihlelo bo batsi ba ho sebetsa ka lipolasetiki tse tloaetseng ho senyeha nakong ea ts'ebetso, joalo ka POM le ABS.

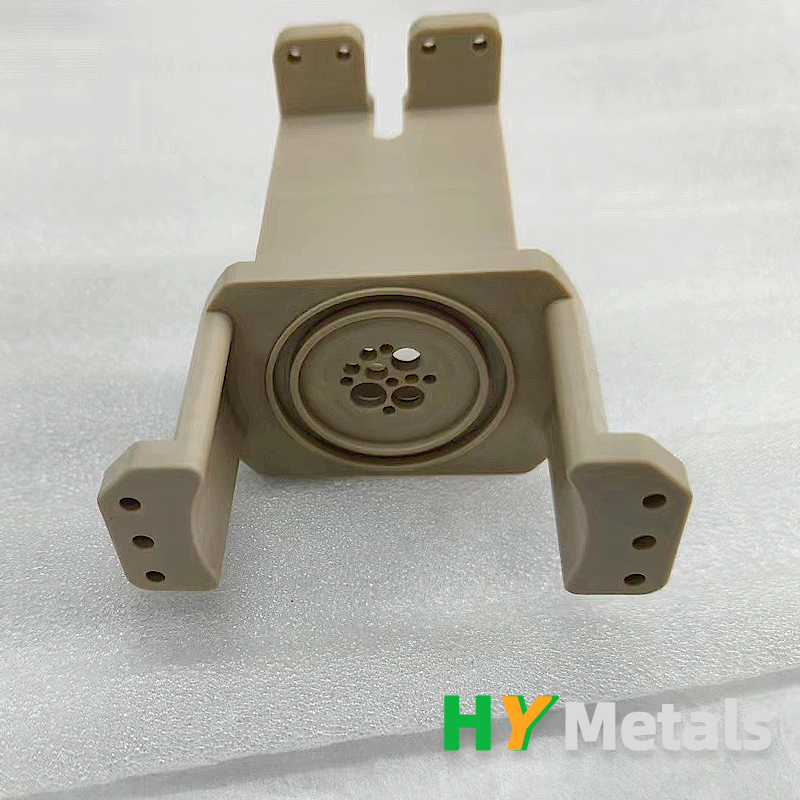

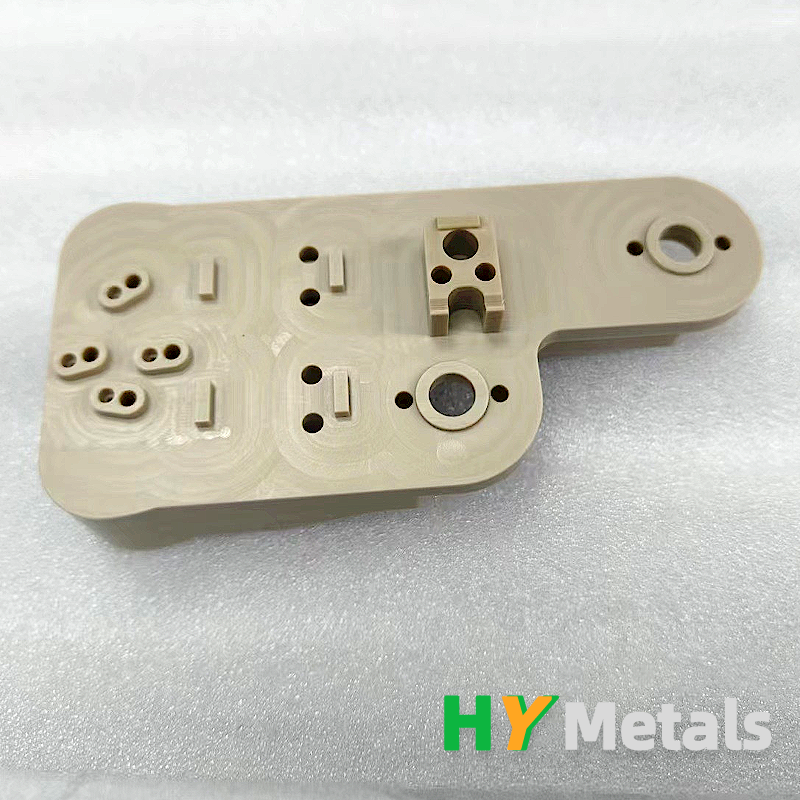

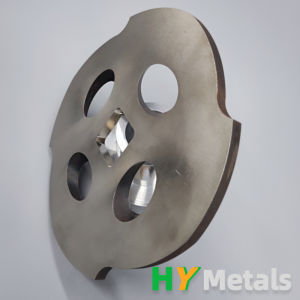

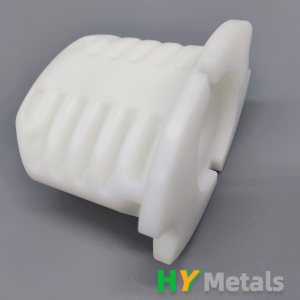

E 'ngoe ea lisebelisoa tseo re ipabolang ho tsona ke PEEK, thermoplastic e sebetsang hantle haholo e tsebahalang ka ho hanyetsa mochini le lik'hemik'hale tse ntle haholo. Machining PEEK e hloka botsebi le ho nepahala, haholo ha o sebetsana le likarolo tse nang le meaho e rarahaneng le mamello e thata.Ho HY Metals, re atlehile ho kenya likarolo tse ngata tsa PEEK tsa boleng bo holimo, tsa boleng bo holimo ho fihlela litlhoko tse ikhethang tsa bareki ba rona.

Ho HY Metals, re utloisisa hore litlhokahalo tsa likarolo tsa mochini oa CNC tse nepahetseng li ka fapana haholo. Re tsepamisitse maikutlo holim'a likarolo tsa sehlahisoa tse kang tlhahiso ea boleng bo tlaase, litlhoko tse nepahetseng tse phahameng, nako e khutšoanyane ea ho fetola, le bokhoni ba ho sebetsana le lisebelisoa tse thata joaloka PEEK li re khetholla ho bahlahisi ba bang. Hore na bareki ba rona ba hloka prototyping kapa tlhahiso e phahameng haholo, re na le bokhoni le boiphihlelo ba ho fihlela litlhoko tsa bona ka boemo bo holimo ba ho nepahala le boleng.

Ho akaretsa, HY Metals e ikemiselitse ho fa bareki likarolo tsa mochini oa CNC tsa boemo ba pele, ho kenyeletsoaLikarolo tsa polasetiki tse entsoeng ka mochini oa CNCle likarolo tsa mochini oa PEEK. Ka lisebelisoa tse tsoetseng pele tsa ts'ebetso, basebetsi ba nang le boiphihlelo le boitlamo ba ho nepahala le boleng, re khona ho fihlela litlhoko tse fapaneng tsa bareki ba rona ho pholletsa le liindasteri tse fapaneng. Ka lebaka la ho shebana le ho nepahala ho phahameng le phetoho e khutšoane, re molekane oa hau ea ratoang bakeng sa litlhoko tsohle tsa machining tsa CNC.