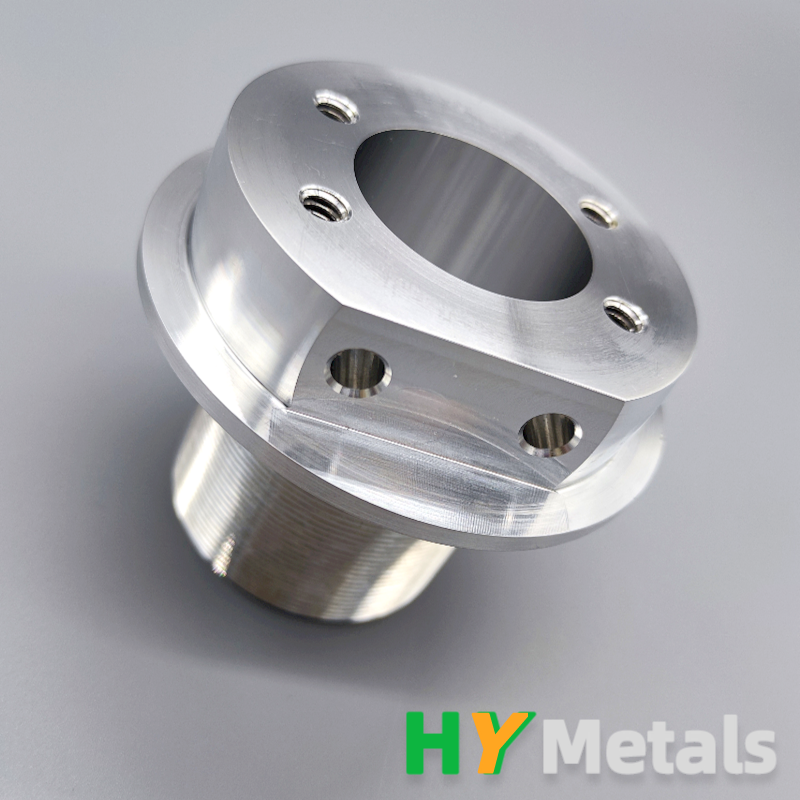

Likarolo tse fetolehang tsa CNC tse nepahetseng hantle tse nang le likhoele tsa kantle tse entsoeng ka mochini

CNC e fetohake ts'ebetso ea bohlokoa bakeng sa ho hlahisa likarolo tsa boleng bo holimo tse entsoeng ka mochini oa CNC. Ka ho khetheha,CNC e fetohalikhoele tsa ka ntle ke ts'ebetso e phephetsang e hlokang ho nepahala le botsebi ho fihlela sephetho se lakatsehang. Ho HY Metals re na le boiphihlelo le theknoloji e tsoetseng pele e hlokahalang ho hlahisa likarolo tsa mochini tsa CNC tsa boleng bo holimo tse nang le likhoele tse entsoeng ka nepo.

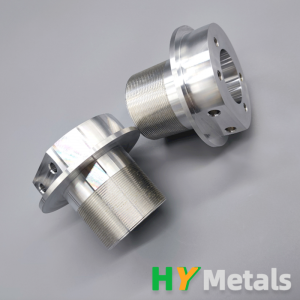

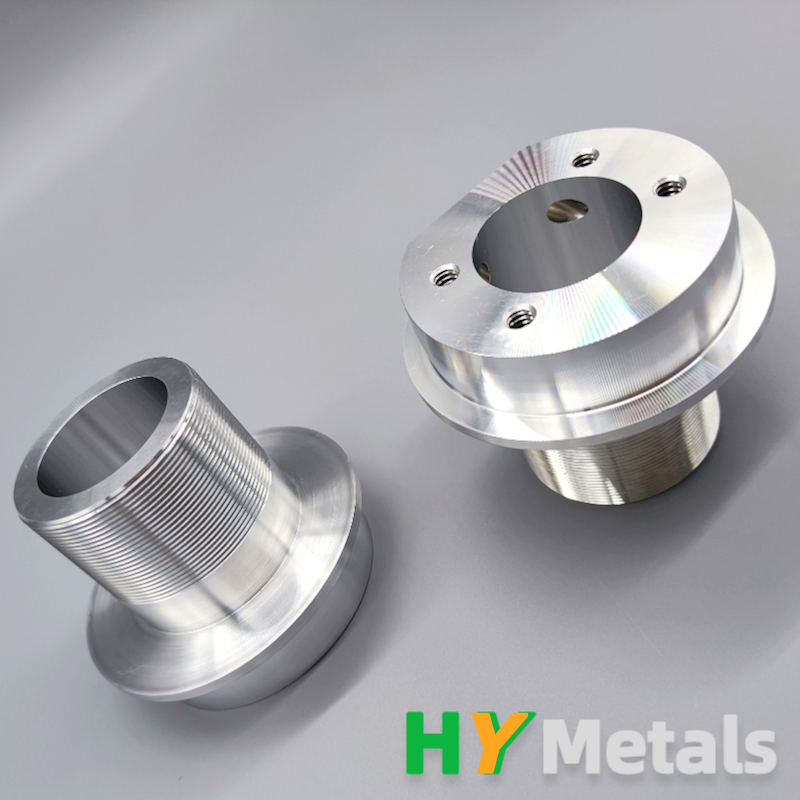

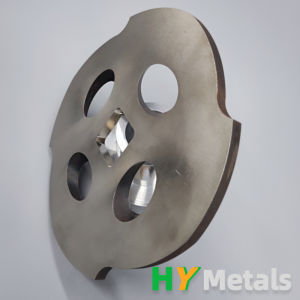

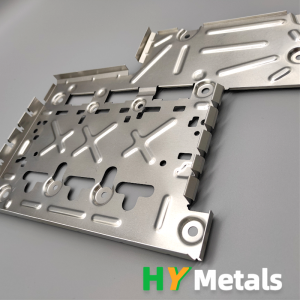

Ka tlase ke tse ling tsa likarolo tseo re li hlahisitseng re sebelisa mekhoa ea ho fetola le ho sila ea CNC re sebelisa thepa ea AL6061. Bakeng sa likhoele tse nyane tse ka hare hangata re sebelisa likoti tse tapped, athe likhoele tse kantle re lula re sebelisa ho reteleha e le tharollo e molemohali. Sephetho ke karolo e bonts'ang sebaka se nepahetseng, sa boleng bo holimo le se entsoeng hantle.

Re motlotlo hore ebe re tsetetse hahololisebelisoa tsa tlhahiso le lisebelisoa,ho kenyelletsa le lathes 60 le ho feta 150 CNC Mills, hammoho le mechine e sila. Ka bokhoni bona, re ka hlahisa ntle le ho sekisetsa ka ho nepahala kapa boleng ba mefuta eohle ea tšepe e kenyelletsang tšepe, tšepe e sa hloekang, tšepe ea lisebelisoa, motsoako oa aluminium, koporo, li-alloys tsa zinki le mefuta e mengata ea polasetiki e kang PC, Nylon, POM, PTFE le PEEK.

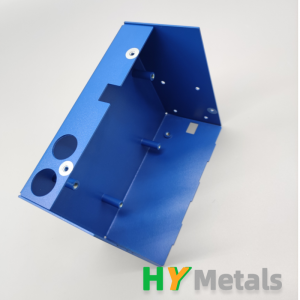

E 'ngoe ea melemo ea mantlha ea ho fetoha ha CNC ke hore e sebetsa hantle ebile e tenyetseha, e re lumellang ho hlahisa likarolo tsa libopeho tse fapaneng, boholo le mathata. Ho phaella moo, li-lathe tsa CNC li sebetsa haholo, li fokotsa kotsi ea phoso. Ka lebaka leo, re ka fihlela mamello e haufi haholo le liphetho tse ntle tsa bokaholimo ka nepo e ka phetoang, leha e le likarolong tse rarahaneng haholo.

Ts'ebetsong ea rona ea ho fetola CNC, re tsepamisitse maikutlo ho ntlafatseng mekhoa ea rona ea ho hlahisa likhoele tsa kantle, ho netefatsa hore likhoele tsohle li bōpehile hantle, li khaoloa ka bophara bo nepahetseng, 'me li na le sekhutlo se nepahetseng. Mekhahlelo ena ea bohlokoa e netefatsa ho lumellana hantle le likarolo tsa ho nyalana le ho matlafatsa thepa ea mochine ea sehlahisoa sa ho qetela. Re sebelisa software e tsoetseng pele ea mananeo ho kenya litekanyo tse nepahetseng, ho netefatsa hore sehlahisoa sa ho qetela se kopana le litlhaloso tsohle tsa bareki.

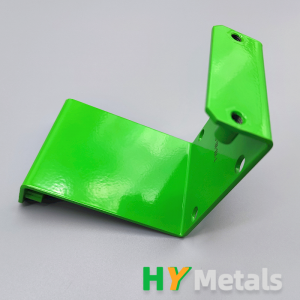

Ho HY Metals, re utloisisa bohlokoa ba hoboleng, ho nepahala le linako tsa ho kopana. Re ikitlaelletsa ho tlisa lihlahisoa tsohle ka nako le ka maemo a holimo. Re ikemiselitse ho fana ka litšebeletso tse ntle tsa bareki, re sebetsa haufi-ufi le bareki ho netefatsa hore likarolo tsa ho qetela li kopana le litlhaloso le litlhoko tsohle.

HY Metals ke ea haulebenkele le le lenghaeba o hloka likarolo tsa mochini oa CNC tse nang le likarolo tsa khoele tse kantle. Re na le boitseanape, boiphihlelo le theknoloji ea ho hlahisa likarolo tse nepahetseng, tsa boleng bo holimo tse nang le bokaholimo bo entsoeng hantle. Re fana feela ka mokhoa o motle ka ho fetisisa oa ho fetola CNC le ho sila, u ke ke ua soetseha. Ikopanye le rona kajeno bakeng sa qotsulo e tloaelehileng kapa ho ithuta haholoanyane ka lits'ebeletso tsa rona tsa mochini oa CNC.