Likarolo tsa Plastiki tse Phahameng ka ho Fetisisa tse entsoeng ka mochini

CNC e tloaelehilenge entsoeng ka mochinilikarolo tsa polasetiki li ntse li ata haholo liindastering tse fapaneng. Likarolo tsena tsa polasetiki li sebelisoa lits'ebetsong tse fapaneng mme li fana ka melemo e mengata ho feta lisebelisoa tse ling. Li-plastiki tsa setso tse kang nylon, FR4, PC, acrylic, le polasetiki ea boenjiniere li 'nile tsa sebelisoa haholo liindastering tse ngata. Leha ho le joalo, ka nts'etsopele ea lisebelisoa tse ncha tsa polasetiki, likhetho tse kang POM le PEEK li se li fumaneha, tse fanang ka matla a maholo le nako e telele.

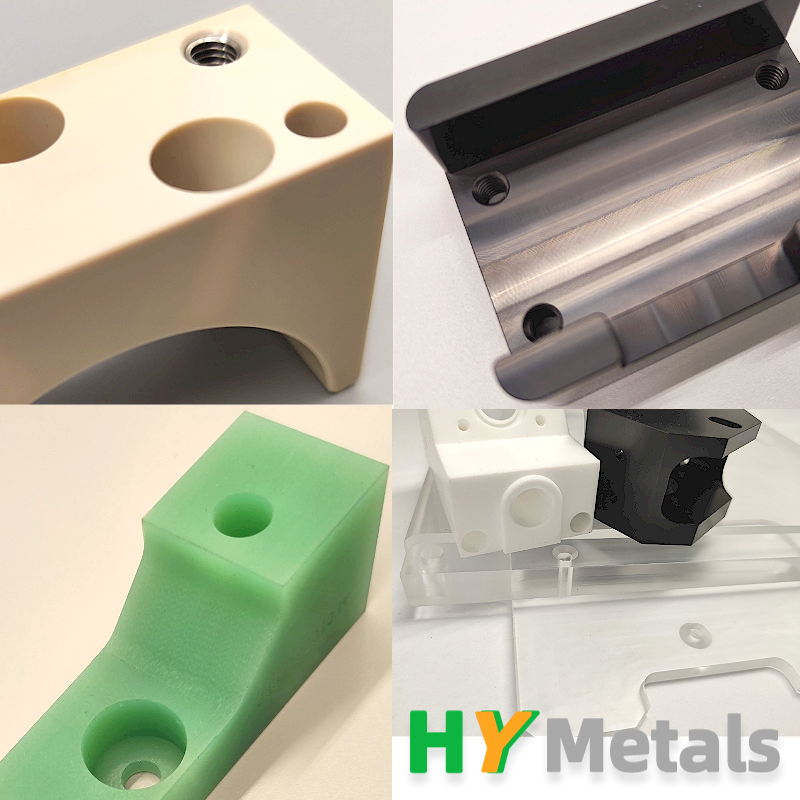

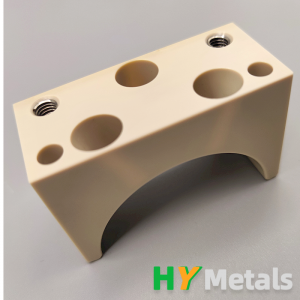

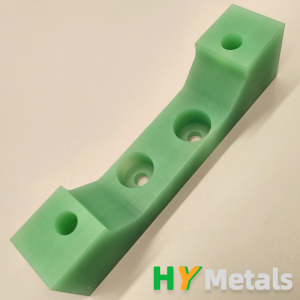

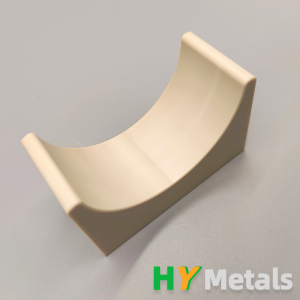

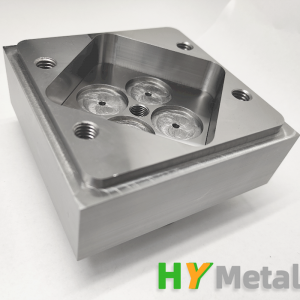

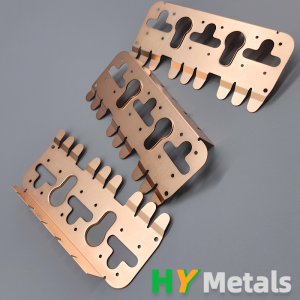

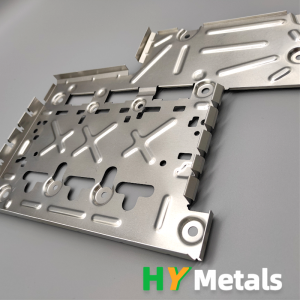

HY Metals, k'hamphani ea tlhahiso e sebetsanang le machining a sheet metal le CNC, e fana ka lihlahisoa tse entsoeng ka thepa e ncha ea polasetiki. Mona ke likarolo tse ling tsa polasetiki tse entsoeng ka thepa e fapaneng ea polasetiki:

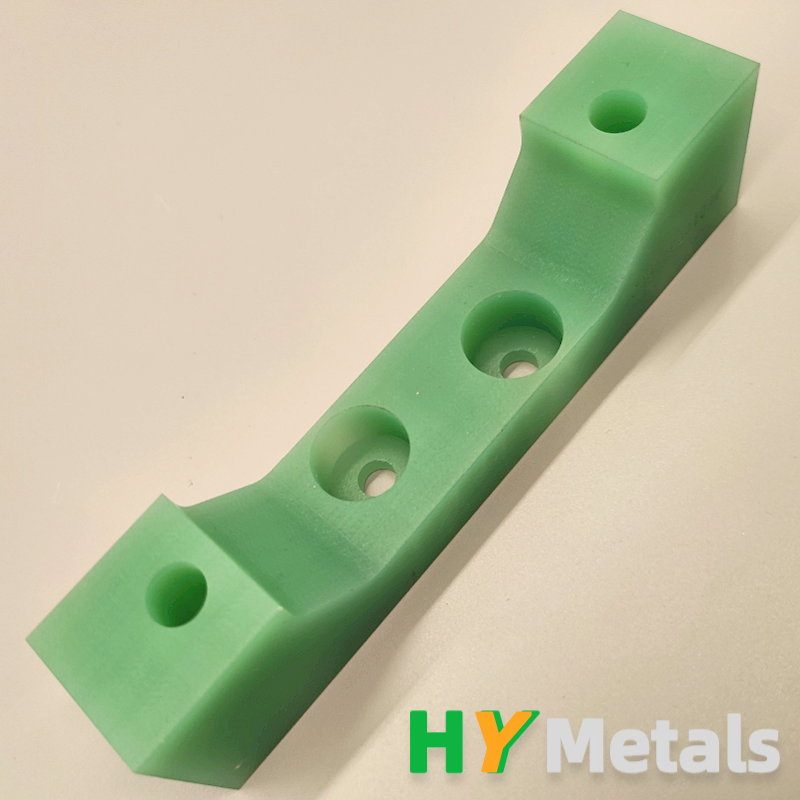

FR4: Likarolo tsa polasetiki tse tala li sebetsoa ka FR4. Thepa ke thepa e kopantsoeng e entsoeng ka lesela le lohiloeng la khalase e le thepa ea motheo le sekhomaretsi sa epoxy resin. E sebelisoa haholo ka thepa ea elektronike ka lebaka la thepa ea eona e phahameng ea insulating le mekhoa e metle ea ho hanyetsa mechine, mocheso le lik'hemik'hale.

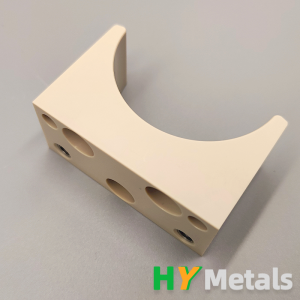

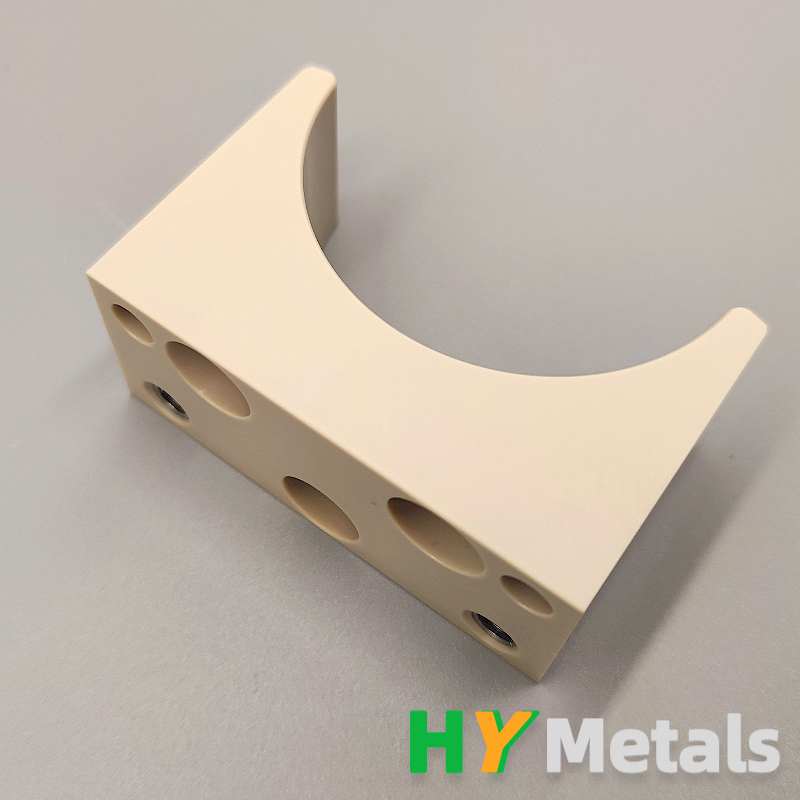

PEKE: Karolo ea polasetiki e sootho e na le coil e kenyang 'me e entsoe ka PEEK, thepa e thata le e theko e boima e nang le thepa e babatsehang ea mochine le ea mocheso. PEEK e khona ho mamella mocheso o phahameng le likhatello, ea e etsa sesebelisoa se loketseng indasteri ea lifofane, tsa likoloi le tsa oli le tsa khase.

POM: Likarolo tsa polasetiki tse ntšo li entsoe ka mochini ho tloha POM (e tsejoang hape e le acetal), thermoplastic e nang le matla a matla a mochini, ho satalla le botsitso ba sebopeho. E sebelisoa haholo ka likere, li-bearings le lits'ebetso tse ling tsa mojaro o phahameng.

Likarolo tsena tsohle tsa polasetiki ke likarolo tse nepahetseng haholo tse sebetsitsoeng ke CNC. Ho nepahala ho bohlokoa ha ho etsoa likarolo tsa polasetiki, 'me machining a CNC a netefatsa ho nepahala le ho tsitsa karolong e' ngoe le e 'ngoe. CNC machining ke mokhoa oa moruo, o sebetsang hantle le o nepahetseng oa ho etsa likarolo tsa maemo a thata a fapaneng.

HY Litšepe e na le ho fetaMechini e 150 ea ho sila ea CNC le likhoele,e ka fanang ka likarolo tse nepahetseng haholo bakeng salisebelisoa tsa tšepe le polasetiki.HY Litšepee na le3 CNClithupelo tsa ho sebetsa le4 lifeme tsa tšepe tsa pampiri, e ka tšehetsang litaelo tsa boholo bo fapaneng ho tsoa ho bareki ba fapaneng. Re fana kalitharollo tse hlophisitsoengho latela litlhoko tsa bareki, ho netefatsa lihlahisoa tsa boleng bo holimo tse fihlelang kapa tse fetang litekanyo tsohle.

Ka kakaretso, likarolo tsa polasetiki tse entsoeng ka CNC tse tloaelehileng li fana ka melemo e 'maloa ho feta lisebelisoa tsa setso.Tšebeliso ea lipolasetiki tsa boenjiniere tse phahameng tse kang PEEK le POM li eketsa matla, ho tšoarella le ho hanyetsa maqheka.CNC machining e tiisa ho nepahala, ho tsitsisa le ho tšepahala ha karolo ka' ngoe.

E le moetsi ea ka sehloohong oaletlapa la tšepeleCNC e entsoe ka mochinilikarolo, HY Metals e ka fana ka likarolo tsa boleng bo holimo tse entsoeng ka thepa e fapaneng ho fihlela litlhoko tsa bareki. Ikopanye le rona kajeno ho fumana hore na re ka u thusa joang ka morero oa hau.