HY Metals e Fana ka Ho nepahala ho Phahameng CNC e Fetotse Karolo ka Nako ea Rekoto

E Phethahetseng ka nepo: HY Metals e Fana ka Complex CNC e Fetotse Karolo ka Nako ea Rekoto

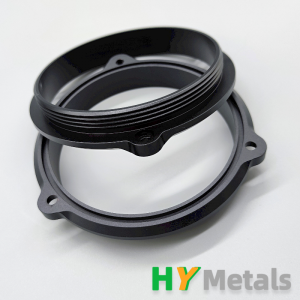

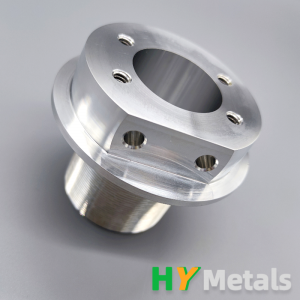

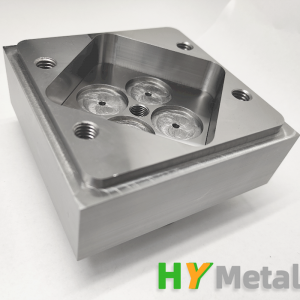

Re thabetse ho hlahisa tsa rona tsa morao-raoCNC e fetotse karolo- Karolo e nepahetseng ea AL6061-T6 e entsoeng ka bokhabane (Ø30mm×25mm) e nang le masoba a mangata a kentsoeng ho kenyelletsa likhoele tsa NPS 1/4-18. Odara ena ea likotoana tse 200 e phethetsoe ka matsatsi a 9 feela ho tloha tlhahlobong ea ho qetela, e bonts'a boitlamo ba HY Metals ba phetoho e potlakileng ntle le ho senya boleng.

Litlhaloso tsa Morero le Liphephetso

- Boitsebiso: AL6061-T6 (karolelano e ntle ea matla ho isa ho boima ba 'mele)

- Likarolo tsa Bohlokoa:

- Likoti tse ngata tse nang le mamello e tiileng ea maemo

- NPS 1/4-18 masoba a khoele a hlokang ho cheka pompo e nepahetseng

- Methati e se nang Burr bakeng sa ho itokisetsa kopano hanghang

- Palo: li-pcs tse 200 (tlhahiso ea li-batch tse nyane)

- Nako ea nako: matsatsi a 9 ho tloha ho odara ho isa boleng bo rometsoeng

Hobaneng Sena se le Bohlokoa Bakeng sa Tlhahiso e nepahetseng

1. Katleho ea Mamello e Menyenyane

- Khoele ea khoele ka har'a ± 0.01mm

- Bokhopo ba sefahleho Ra 0.8μm (qetello ea boleng ba seipone)

- Ho lumellana hoa likarolo tsohle tse 200

2. Tlhahiso e Potlakileng ea Batch e Nyane

- Ha ho na lithibelo tse fokolang tsa ho laela

- 30% tlhahiso e potlakileng ho feta maemo a indasteri

- Ho qotsa letsatsi le le leng bakeng sa likarolo tse fetotsoeng

3. Bokhabane ba Ts'ebetso ea Bobeli

- Deburring: Ho thella ha mochini bakeng sa phetheho

– Ho hloekisa: Kalafo ea ho hlapa ka mokhoa oa Ultrasonic

- Ho paka: Likarolo tsa motho ka mong tse thibelang ho opa

HY Metals'Ho fetoha ha CNCMelemo

✅ 15+ Switzerland-mofuta oa CNC Lathes (0.001mm ho nepahala)

✅ Bokhoni ba ho sebelisa lisebelisoa (ho sila / ho tlanya ka setaele se le seng)

✅ Ho hlahloba likhoele ka tlung (tekanyo ea khoele ea 100%)

✅ Setifikeiti sa lintho tse bonahalang (traceability e felletseng)

Melemo ea Bareki e Lemohile

- Potoloho e felletseng ea matsatsi a 9 (ha e bapisoa le karolelano ea libeke tse 3 tsa indasteri)

- Sekhahla sa ho se sebetse hantle tlhahlobong ea sengoloa sa pele

- Ho boloka litšenyehelo tsa 25% ka maano a ntlafalitsoeng a mochini

- Litlhahiso tsa DFM tse ntlafalitseng ho tšoarella ha karolo

Phapang ea rona ea Theknoloji

✔ Khokahano ea Smart Feme

- Tlhokomelo ea tlhahiso ea nako ea sebele

- Puseletso ea ho roala lisebelisoa tse ikemetseng

- Lintlafatso tsa tsoelo-pele tse thehiloeng marung

✔ Protocol ea Tiisetso ea Boleng

- netefatso ea CMM ea sehlooho sa pele

- Lichate tsa taolo ea ts'ebetso ea lipalo

- Litlaleho tsa ho qetela tsa tlhahlobo li kenyelelitsoe

Liindasteri Tse Sebeletsoeng

- Liroboto: Likarolo tse kopaneng le likarolo tsa actuator

- Bongaka: Matlo a liletsa

- Aerospace: Lintho tse bobebe tsa sebopeho

- Likoloi: Lisebelisoa tsa sensor le lisebelisoa

Tharollo ea Karolo ea Hao e Fetohileng e Letetse

Hore na o hloka:

- Bongata ba prototype (li-pcs tse 1-50)

- Tlhahiso ea borokho (50-1,000 pcs)

- Ho etsa lihlahisoa tse phahameng (10,000+ pcs)

HY Metals e fana ka: