Likarolo tsa tšepe tsa Sheet le likarolo tse entsoeng ka mochini oa CNC hangata li entsoe ka lisebelisoa tse fapaneng, ho kenyeletsoa tšepe e sa hloekang, aluminium, koporo, koporo, boronse, titanium le lisebelisoa tse fapaneng. Lithako tse atileng haholo tsa likarolo tsa tšepe li kenyelletsa ho roala phofo, anodizing, plating, galvanizing le pente. Likarolo tse entsoeng ka mochini oa CNC le tsona li ka phethoa ka mekhoa e fapaneng, joalo ka ho bentša, ho qhomisa lehlabathe, le ho buffing. Ho itšetlehile ka kopo, phekolo e eketsehileng le liphahlo li ka sebelisoa ho ntlafatsa ts'ebetso le ponahalo ea likarolo.

HY metals ke mofani oa hau ea molemo ka ho fetisisa oa likarolo tsa tšepe tsa lakane le likarolo tsa machining tse nang le boiphihlelo bo fetang lilemo tse 10 le ISO9001: cert ea 2015. Re na le lifeme tse 6 tse hlometseng ka botlalo ho kenyeletsoa mabenkele a 4 a tšepe le a 2 a CNC.

Re fana ka profeshenale tšepe tloaelo le polasetiki prototyping le ho etsa tharollo.

HY Metals ke k'hamphani e hlophisitsoeng e fanang ka ts'ebeletso e le 'ngoe ho tloha thepa e tala ho felisa lihlahisoa tsa tšebeliso.

Re ka sebetsana le mefuta eohle ea thepa ho kenyeletsoa tšepe ea Carbon, tšepe e sa hloekang, tšepe ea Tool, Brass, Aluminium, le mefuta eohle ea polasetiki e machable.

Boitsebiso le Qetella Likarolo tsa Metal tsa Sheet

Bakeng sa sehlopha se thata, lisebelisoa tsa tšepe tsa sheet li kenyelletsa haholoCarbon Steel,Ts'epe e sa beng le mabali,Aluminium AlloyleMotsoako oa Koporo4 lihlopha tse kholo.

Le sheet metal finishes haholo-holo kenyeletsaHo roala borashe,Ho benya,Electroplating,Ho roala ka phofo,Ho pentaleAnodizing.

Tšepe ea carbonke e 'ngoe ea lisebelisoa tse sebelisoang ka ho fetesisa ha ho etsoa masela a tšepe. E matla ho feta Aluminium mme e theko e tlase haholo ho feta Stainless steel.

Empa ho hlakile hore tšepe e ka rusoa habonolo. Ebe ho qeta ho roala ho tla hlokahala bakeng sa likarolo tsa tšepe.

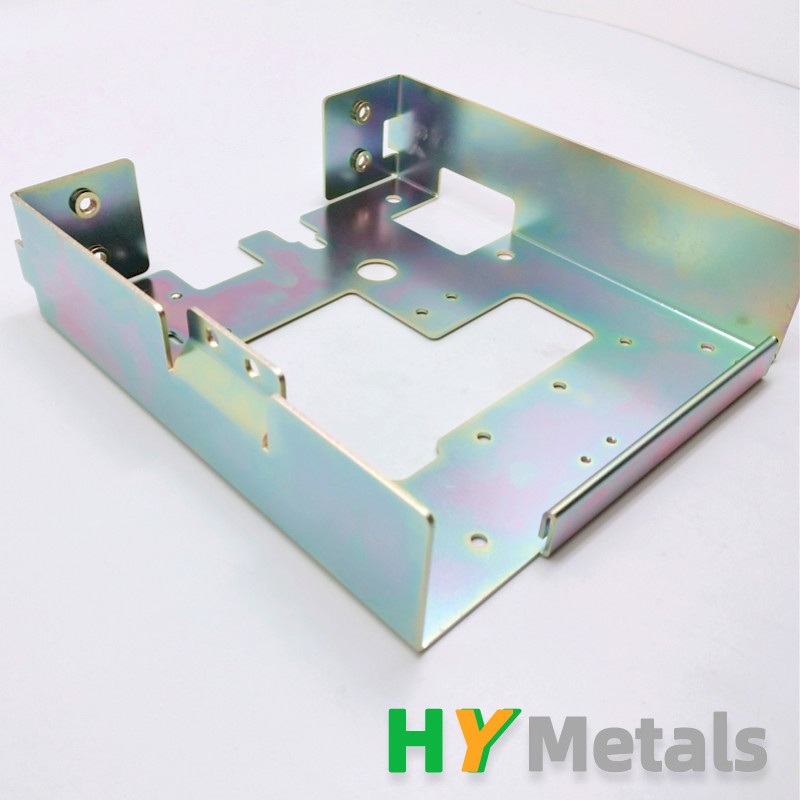

Likarolo tsa Metal tse tsoang ho tšepe ea carbon e nang le Zinc plating

Zinc plating,Nickel plating le chrome plating e atisa ho sebelisoa likarolong tsa tšepe tsa tšepe bakeng sa morero oa ho thibela ho bola. Ka linako tse ling plating e boetse e phetha karolo ea mokhabiso.

Tšepe e sa hloekang e nang le 2B finish, boloka feela thepa e tala.

Ka linako tse ling ho fumana setlolo holim'a setlolo, re tla etsa borashe qetellong holim'a likarolo tsa tšepe tse sa hloekang.

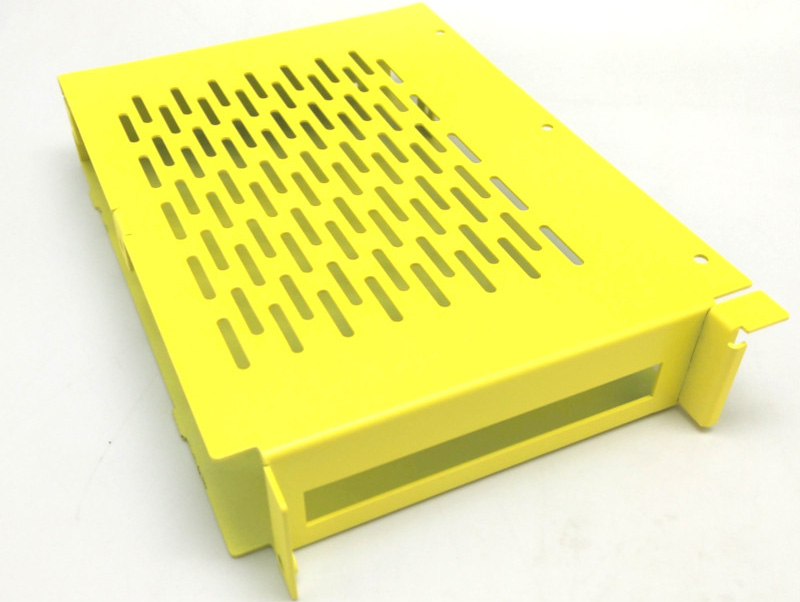

Likarolo tsa Metal tsa Sheet tse tsoang ho tšepe ea carbon le Powder e tlotsitsoeng Bosehla

Ho roala ha phofo ke mofuta oa epoxy resin resin, botenya ba eona bo lula bo le pakeng tsa 0.2-0.6mm, botenya haholo ho feta plating layer.

Powder Coat finish e loketse likarolo tse ling tsa tšepe tse kantle tse sa mamelleheng 'me li batla ho fumana mebala e ikhethileng.

Stshepe e senang tshepee na le bokhoni bo betere ba ho hanyetsa mafome, e sebelisoang haholo lisebelisoa tsa boiketsetso, sesebelisoa sa bongaka, thepa ea kichineng le mefuta e mengata ea masaka a kantle, likhetla.

Ts'epe e sa beng le mabalilikarolo hangata ha li hloke pheletso, boloka feela thepa e tala ka 2B finish kapa Brushed finish.

Tšepe e sa hloekang e nang le phello e fapaneng ea borashe

Amotsoako oa aluminiume sebelisoa haholo sebakeng sa sefofane le likhetla tsa lisebelisoa tse ling ho fokotsa boima ba 'mele le ho fumana tšireletso e ntle ea mafome.

Ka nako e ts'oanang, alloy ea aluminium e boetse e na le bokhoni bo botle ba 'mala ha ho etsoa anodizing.

U ka fumana 'mala ofe kapa ofe o motle oo u o batlang likarolong tsa hau tsa tšepe tsa aluminium.

Clikarolo tsa tšepe tsa ustom tse nang le qetello e fapaneng

Letlapa la 1. Lintho tse Tloaelehileng le Qetella likarolo tsa tšepe tsa sheet

Sandblasting and anodizing finishes holim'a aluminium extruded tubes.

Sandblast finish e ka koahela mefokolo ea thepa kapa matšoao a lisebelisoa a likarolo tse entsoeng ka mochini. Anodizing e ka fumana bokhoni ba anti-corrosion mme ka nako e ts'oanang ea fumana 'mala o loketseng likarolo tsa aluminium.

Kahoo sandblasting+ anodizing ke khetho e phethahetseng haholo bakeng sa likarolo tsohle tsa litlolo tsa aluminium.

| Mlisebelisoa | Thickness | Qetella | |

| Tšepe e batang | SPCC SGCC SECC SPTE Tšepe e entsoeng ka thini | 0.5-3.0 limilimithara | Ho roala ka phofo (Mebala e ikhethileng e teng) Penta e metsi (Mebala e ikhethileng e teng) Silkscreen Ho roala zinki (Ho hlakile, Putsoa, Mosehla) Nickel plating Chrome plating E-coating, QPQ |

| Tšepe e kolobisitsoeng e chesang | SPHC | 3.0-6.5mm | |

| Otšepe e bonolo | Q235 | 0.5-12 limilimithara | |

| Stshepe e senang tshepe | SS304,SS301,SS316 | 0.2-8mm | 2B Qetella thepa e tala, Brushed thepa e tala Brush, ho benya Motlakase oa poleishene Passivate |

| Stšepe ea tšepe Suit bakeng sa likotoana tsa selemo | SS301-H,1/2H,1/4H,3/4H |

| Ha ho letho |

| Mn65

|

| Phekolo ea mocheso | |

| Aluminium | AL5052-H32, AL5052-H0 AL5052-H36 AL6061 AL7075 | 0.5-6.5 limilimithara | Filimi e hlakileng ea lik'hemik'hale Anodizing, anodizing e thata (Mebala e ikhethileng e teng) Ho roala ka phofo (Mebala e ikhethileng e teng) Penta e metsi (Mebala e ikhethileng e teng) Silkscreen Ho qhomisa lehlabathe Sandblast + Anodize Electroless Nickel plating Brush, Sepolishe |

| Brass | E sebelisoa haholo ho Lisebelisoa tsa elektroniki, likarolo tsa khokahanyo tsa conductive | 0.2-6.0mm | Ho roala thini Nickel plating Ho khabisa ka khauta Qetello ea thepa e tala |

| Copper | |||

| Beryllium Copper Phosphor koporo | |||

| Motsoako oa silevera oa Nickel | Lisebelisoa tsa elektronike | 0.2-2.0mm | Lisebelisoa tse so ntlafatsoe |

Boitsebiso le Qetella bakeng sa likarolo tsa CNC Machined

Lisebelisoa tse sebelisoang hangata bakeng sa likarolo tsa machining tsa CNC ho kenyelletsa tšepe, tšepe e sa hloekang, Aluminium, Brass, le mefuta eohle ea thepa ea polasetiki e ka sebelisoang.

Likarolo tsa CNC hangata li ne li hloka mamello e thata, kahoo lera la ho roala ha le lumelloe le le tenya haholo.

Electroplating bakeng sa likarolo tsa tšepe le koporo , anodizing bakeng sa likarolo tsa aluminium ke tsona tse qetellang ka ho fetisisa.

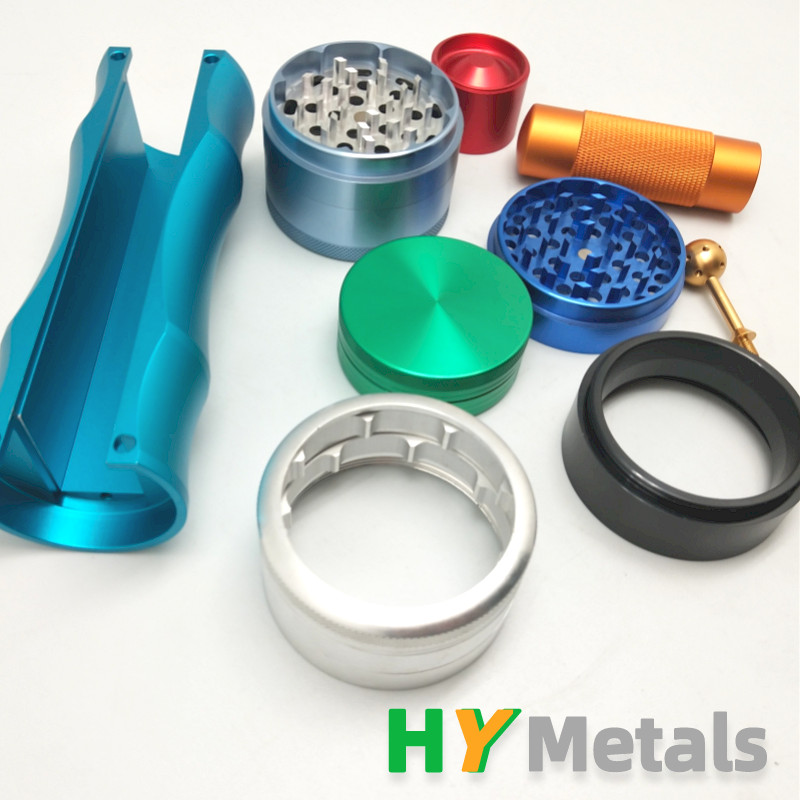

Clikarolo tsa ustom tsa CNC tse nang le liphetho tse fapaneng

Sandblasting and anodizing finishes holim'a aluminium extruded tubes.

Sandblasting and anodizing finishes holim'a aluminium extruded tubes.

Sandblast finish e ka koahela mefokolo ea thepa kapa matšoao a lisebelisoa a likarolo tse entsoeng ka mochini. Anodizing e ka fumana bokhoni ba anti-corrosion mme ka nako e ts'oanang ea fumana 'mala o loketseng likarolo tsa aluminium.

Kahoo sandblasting+ anodizing ke khetho e phethahetseng haholo bakeng sa likarolo tsohle tsa litlolo tsa aluminium.

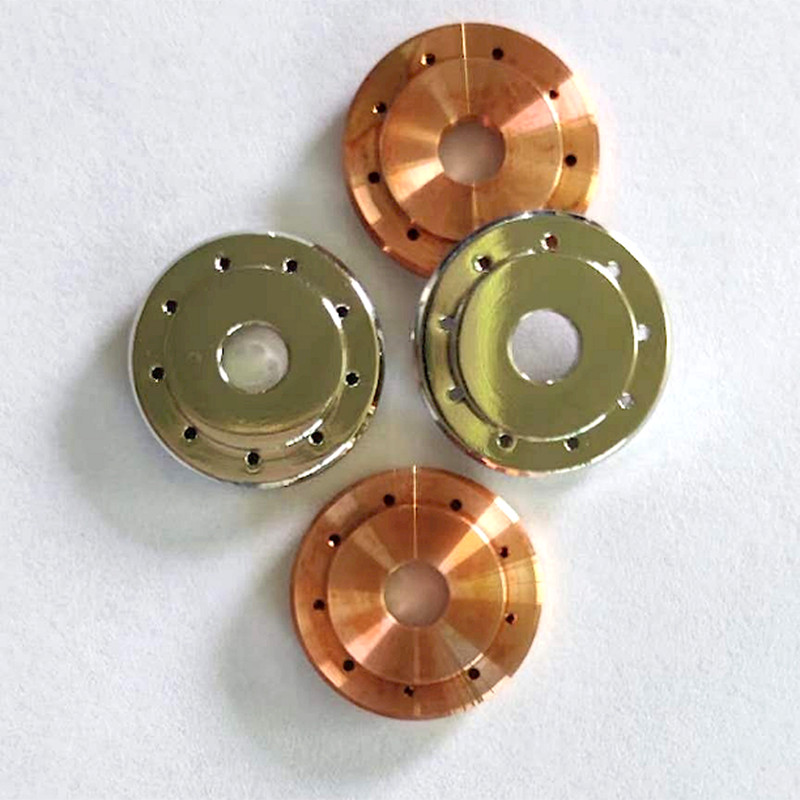

Likarolo tsa koporo tse nang le nickel plating finish

Bakeng sa likarolo tsa alloy ea koporo, phekolo e sebelisoang haholo ka holim'a metsi ke tin plating le nickel plating..

Letlapa la 2. Lintho tse Tloaelehileng le Qetella likarolo tsa machining tsa CNC

| Plastic le Qetella | Metal alloy | Finish | |

| ABS | Amotsoako oa aluminium | AL6061-T6,AL6061-T651 | Deburr, Sepolishe, Brush |

| Nylon | AL6063-T6, AL6063-T651 | Anodize, anodize e thata | |

| PC | AL7075 | Sandblast | |

| POM(Delrin) | AL1060,AL1100 | Letlapa la nickel le se nang motlakase | |

| Acetal | AL6082 | Chromate / chrome chemical filimi | |

| PEEK | Stshepe e senang tshepe | SUS303,SUS304,SUS304L | Passivate |

| PPSU(Radel® R-5000) | SUS316,SUS316L | Joalo ka mochini | |

| PSU | 17-7 PH, 18-8 PH | Joalo ka mochini | |

| PS | Ttšepe ea tšepe | A2, # 45, tšepe e 'ngoe ea lisebelisoa | Phekolo ea mocheso |

| PEI(Ultem2300) | Mild steel | Sttlhapinohana12L14 | Nickel / chrome plating |

| HDPE | Brass | Joalo ka mochini | |

| PTFE(Teflon) | Copper | C36000 | Nickel/Gold/Tin plating |

| PMMA(Akriliki) | Zinc motsoako | Joalo ka mochini | |

| PVC | Titanium | 6Al-4V | Joalo ka mochini |