Indastering ea kajeno ea tlhahiso, ho fetola CNC, mochini oa CNC, ho sila ka CNC, ho sila le mekhoa e meng e tsoetseng pele ea machining e sebelisoa ho theha likarolo tsa tšepe tse tloaelehileng tse nang le mamello e thata. Mokhoa oa ho theha likarolo tse entsoeng ka mokhoa o nepahetseng o hloka motsoako oa tsebo ea tekheniki, bokhoni le botsebi.

Mohato oa pele oa ho theha karolo e entsoeng ka mokhoa o nepahetseng haholo ke ho hlahloba ka hloko litlhaloso tsa moralo. Litlhaloso tsa moralo li tla kenyelletsa litekanyo tse qaqileng, mamello le litlhoko tsa thepa. Baetsi ba mananeo ba CNC ba lokela ho hlahloba ka hloko litlhaloso tsa moralo ho netefatsa hore mochini oa CNC o hlophisitsoe ka nepo le lisebelisoa tse nepahetseng li sebelisoa.

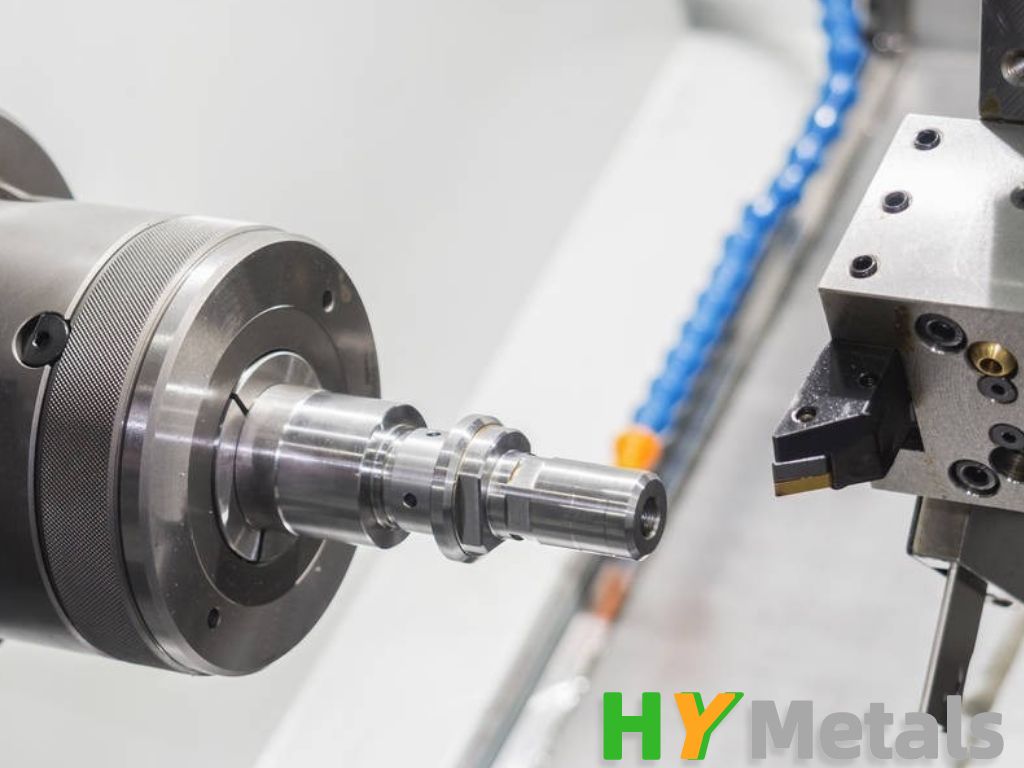

Mohato o latelang ke ho fetola CNC. Ho fetola CNC ke mokhoa oa ho fetola tšepe ea tšepe ho sebelisa mochine o laoloang ke k'homphieutha le ho tlosa lintho tse tsoang holimo ho sebelisa lisebelisoa tsa ho itšeha. Mokhoa ona o sebelisetsoa ho etsa likarolo tsa cylindrical kapa chitja tse kang li-shafts kapa bolts.

Hang ha ts'ebetso ea ho fetola CNC e phethiloe, setsebi sa machini se fetela pele ho milling ea CNC. CNC milling e kenyelletsa ts'ebeliso ea mechini e laoloang ke komporo ho tlosa thepa ho tsoa bolokong ea tšepe ho etsa likarolo tse ikhethileng. Mokhoa ona o sebelisetsoa ho etsa likarolo tse rarahaneng tse nang le libopeho tse rarahaneng kapa liqapi.

Nakong ea ho phethoha le ho sila ha CNC, bo-machini ba tlameha ho lekola lisebelisoa tsa ho itšeha ka hloko ho netefatsa hore li lula li le bohale ebile li nepahetse. Lisebelisoa tse bohlasoa kapa tse tsofetseng li ka baka liphoso sehlahisoa sa ho qetela, sa etsa hore likarolo li se ke tsa mamellana.

Ho sila ke mohato o mong oa bohlokoa tšebetsong ea machining e nepahetseng haholo. Ho sila ho sebelisoa ho tlosa lisebelisoa tse nyenyane ho tloha holim'a karolo, ho etsa sebaka se boreleli le ho etsa bonnete ba hore karolo e kopana le mamello e hlokahalang. Ho sila ho ka etsoa ka letsoho kapa ka ho sebelisa mefuta e mengata ea mechine e ikemetseng.

Ho mamellana ka thata ke e 'ngoe ea lintlha tsa bohlokoa ka ho fetesisa ha ho etsoa likarolo tsa mochini o nepahetseng haholo. Ho mamellana ka thata ho bolela hore likarolo li tlameha ho etsoa ho ea ka litekanyo tse nepahetseng, 'me ho kheloha leha e le hofe ho tloha boemong boo ho ka etsa hore karolo e hlōlehe. Ho kopana le mamello e matla, bo-machini ba tlameha ho lekola ts'ebetso eohle ea mochini ka hloko le ho lokisa mechini ha ho hlokahala.

Qetellong, likarolo tsa tšepe tse tloahelehileng li tlameha ho hlahlobjoa ka botlalo ho etsa bonnete ba hore li kopana le litlhaloso tse hlokahalang. Sena se ka kenyelletsa tšebeliso ea lisebelisoa tse khethehileng tsa ho metha kapa tlhahlobo ea pono. Bofokoli bofe kapa bofe kapa likhaello ho tsoa ho litlhaloso tsa moralo li tlameha ho rarolloa pele karolo e ka nkoa e felletse.

Ka bokhutšoanyane, ho etsa likarolo tse entsoeng ka mokhoa o nepahetseng haholo ho hloka tsebo ea tekheniki, tšebeliso ea mekhoa e tsoetseng pele ea mochine, le boitlamo ba ho laola boleng. Ka ho latela mehato ena le ho ela hloko lintlha tse qaqileng, baetsi ba lihlahisoa ba ka hlahisa likarolo tsa tšepe tse tloaelehileng tse finyellang mamello e thata ka ho fetisisa le litekanyetso tsa boleng bo phahameng ka ho fetisisa.

Nako ea poso: Mar-18-2023