-

HY Metals e Fana ka Ho nepahala ho Phahameng CNC e Fetotse Karolo ka Nako ea Rekoto

Litlhaloso tsa Morero le Liphephetso

- Boitsebiso: AL6061-T6 (karolelano e ntle ea matla ho isa ho boima ba 'mele)

- Likarolo tsa Bohlokoa:

- Likoti tse ngata tse nang le mamello e tiileng ea maemo

- NPS 1/4-18 masoba a khoele a hlokang ho cheka pompo e nepahetseng

- Methati e se nang Burr bakeng sa ho itokisetsa kopano hanghang

- Palo: li-pcs tse 200 (tlhahiso ea li-batch tse nyane)

- Nako ea nako: matsatsi a 9 ho tloha ho odara ho isa boleng bo rometsoeng

-

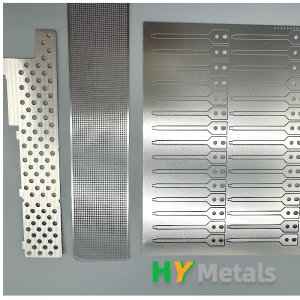

HY Metals e Fana ka Metal Sheet Enclosure Prototypes bakeng sa Teko ea Lisebelisoa

✔ Lintho tse bonahalang: tšepe ea pele ea galvanized (phekolo e khahlanong le kutu)

✔ Palo: Likarolo tse 2 tsa prototype bakeng sa tlhahlobo ea tšimo

✔ Mekhoa ea bohlokoa:

- Ho itšeha ka laser (± 0.1mm ho nepahala)

- Ho kobeha ka nepo (± 0.2° angle ho mamellana)

- Kopano ea Riveting (ho kenyeletsoa ha mochini oa flush)

✔ Boleng ba Bokahohle: Ho roala filimi e sirelletsang e sa horohang

-

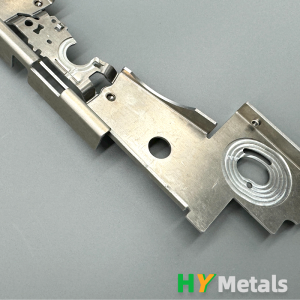

Phetoho ea Liroboto e Tsoelang Pele: Metals ea HY e Fana ka Bracket ea Arm e nepahetseng ea CNC-Machined Robotic Arm.

Ho HY Metals, re motlotlo ho hlahisa sehokelo sa rona sa morao-rao se entsoeng ka mochini oa CNC - bracket ea letsoho e nepahetseng haholo ea AL6061-T6 (bolelele ba 405mm) e etselitsoeng litsamaiso tsa othomathike tsa moloko o latelang. Karolo ena e rarahaneng e bonts'a boiphihlelo ba rona bo ntseng bo hola ba ho sebeletsa indasteri e ntseng e hola ea liroboto ka likarolo tsa bohlokoahali;

-

HY Metals E Eketsa Bokhoni ba Tlhahiso e Nepahetseng ka Likarolo Tse Ncha tse Fetohileng le Likarolo tsa Bongaka.

Ho HY Metals, re thabetse ho hlahisa likarolo tsa rona tsa morao-rao tsa likarolo tse fetotsoeng le likarolo tsa boemo ba bongaka - ho tloha ho likarolo tse entsoeng ka mochini o monyane (Ø3-4mm x 3mm) ho isa ho li-shafts tse kholo (Ø500mm x 1000mm). Ts'ebetso ena e fapaneng ea tlhahiso e bonts'a maemo a rona a ke keng a lekanngoa ho sebeletsa liindasteri ho tloha ho lisebelisoa tsa bongaka ho isa mecheng ea indasteri.

Kopana le Moetapele oa Lihlahisoa

Hore na o hloka:

- Li-prototypes tse entsoeng ka mechine e menyenyane

- Likarolo tse fetotsoeng tse lokiselitsoeng tlhahiso

- Likarolo tse khethehileng tsa bongaka

-

Re hlahisa likarolo tsa rona tsa morao-rao tsa tšepe tse nepahetseng: Ntlafatsa boiphihlelo ba hau ba prototyping

Ho HY Metals, re ikemiselitse ho fana ka litharollo tse ncha ho fihlela litlhoko tse lulang li fetoha tsa bareki ba rona. Likarolo tsa rona tse ncha tsa tšepe tse tloahelehileng, ho kenyeletsoa le likoahelo tse koahetsoeng ka phofo e ntšo tse nang le linate tsa rivet le likaroloana tsa chassis tsa aluminium tse hlakileng, li bonts'a boinehelo ba rona ho boleng le ho nepahala.

Haeba u batla molekane ea tšepahalang bakeng sa hauprototyping ea tšepe ea pampirilitlhoko, se shebe hole ho feta HY Metals. Ikopanye le rona kajeno ho ithuta haholoanyane ka bokhoni ba rona le kamoo re ka u thusang ho phethahatsa morero oa hau!

HYLitšepefanasebaka se le senglits'ebeletso tsa tlhahiso ea moetlo ho kenyeletsaho etsa lesela la tšepeleMechine ea CNC, liphihlelo tsa lilemo tse 14 leMehaho e 8 e nang le thepa ka botlalo.

E kgabaneBolengtaolo,kgutshoanyaneselikalikoe,e kgolopuisano.

Romella RFQ ea hau kalitšoantšo tse qaqilengkajeno. Re tla u qotsa hanghang.

WeChat:na09260838

Bolella:+86 15815874097

Lengolo-tsoibila:susanx@hymetalproducts.com

-

Likarolo tsa Titanium tse entsoeng ka mokhoa o ikhethileng oa CNC tse nang le phetoho ea lithunya

CNC machining le anodizing e latelang ea li-alloys tsa titanium ke mekhoa e rarahaneng e hlokang tsebo e khethehileng, lisebelisoa le theknoloji. Mathata a amanang le machining, joalo ka ho roala lisebelisoa, ho hlahisa mocheso le ho theha chip, hammoho le ho rarahana ha anodizing, ho hatisa tlhokahalo ea moralo o hlokolosi le ts'ebetso. Ha tlhoko ea likarolo tsa ts'ebetso ea titanium e ntse e eketseha ho pholletsa le liindasteri, ho hlola mathata ana ho bohlokoa ho bahlahisi ba ikemiselitseng ho fihlela litekanyetso tse thata tsa boleng le ts'ebetso.

HY Metals e teng bakeng sa ho fana ka litharollo tsa likarolo tsa machining tsa CNC tse nepahetseng ka ho fetesisa tsa Titanium.

-

Sekoaelo sa tšepe sa boleng bo holimo sa aluminium se nang le sandblasting le anodizing e hlakileng

Dimension: Tloaelo ho latela litšoantšo tsa moralo

Mamello bakeng sa ho kobeha lakane tšepe: +/- 0.02mm

lintho tse bonahalang: Koporo, koporo, tšepe e sa hloekang, aluminium, tšepe, SPPC, SGCC, SECC, SPHC, tšepe e batang, tšepe e bonolo

Qetella: Sandblasting, anodizing, lik'hemik'hale filimi, chromate, plating, anodizing, ka litlhoko

QTY: Ho tloha ho 1 pcs prototyping ho isa tlhahiso ea likete-kete

Kopo: Elektronike, bongaka, sebaka sa sefofane, mochine o ikemetseng, oa likoloi

-

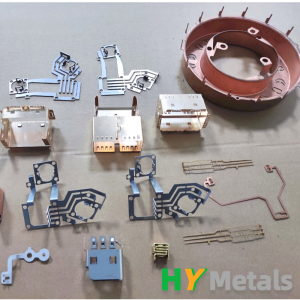

Precision tloaelo lakane tšepe likarolo tsa elektronike contactor

Ea pele ea lihlahisoa tsena tse ncha ke karolo ea 6 mm ea bophara ba elektroniki e nang le selikalikoe sa conductive claw. Ho kobeha ho nepahetseng ho hlokahalang ho etsa selikalikoe se koetsoeng qetellong ea karolo ena ke bopaki ba bokhoni bo tsoetseng pele ba tlhahiso ea HY Metals. Moralo o rarahaneng oa karolo le boholo bo bonyenyane bo hlahisa liphephetso tse ikhethang tsa tlhahiso, empa sehlopha sa rona sa litsebi tsa mesebetsi ea matsoho le mechini ea morao-rao se netefatsa hore karolo ka 'ngoe e kopana le lintlha tse nepahetseng tse thathamisitsoeng setšoantšong.

-

Custom High Precision CNC Fetola likarolo

Dimension: Tloaelo ho latela litšoantšo tsa moralo

Mamello: +/- 0.001mm

lintho tse bonahalang: Koporo, koporo, tšepe e sa hloekang, aluminium, tšepe

Qetella: Joalo ka mochini, ho sila, ho pola, anodizing, ha ho hlokahala

QTY: Ho tloha ho 1 pcs prototyping ho isa tlhahiso ea likete-kete

HY Metals e fana ka ts'ebeletso e le 'ngoe bakeng sa likarolo tse tloaelehileng tsa tšepe le tsa polasetiki tse fetohang nako e khuts'oane

-

Bracket ea Metal Sheet e Tloaelehileng e nang le Precision CNC Machining libaka libakeng tse 'maloa

HY Metals e sa tsoa qeta morero o kenyelletsanglikarolo tsa tšepe tse tloaelehileng entsoe ka Al5052 bakeng samasakana a likoloi.

Kamora hobalaser khaola, kobehileleruveted, bracket e hlokahalangho sebetsa ka nepolibakeng tse 'ne tse khethehileng ho theha li-circles tse hatetsoeng. Li-circles tsena tse hatelitsoeng lia hlokahala ho amohelalikarolo tsa elektronikebakeng sa mokhahlelo o latelang oa kopano. Leha ho na le mathata a ho boloka mamello ea machining kamora ho kobeha, HY Metals e ile ea phethahatsa morero ona ka katleho, ho netefatsa sephetho sa boleng bo holimo.

-

Litšebeletso tsa Precision Metal Etching tse tsoang ho HY Metals: Seamless Part Fixing Solutions

HY Metals e hlahisitse tharollo ea sejoale-joale e felisang tlhoko ea manonyeletso a setso ha o kenya likarolo tse ngata holim'a tšepe ea pampiri. Mokhoa ona o mocha o kenyelletsa ho sebelisa filimi e khethehileng e kentsoeng boitsebisong pele ts'ebetso ea etching e qala. Filimi e sebetsa e le lera le sireletsang, le tšoere ntho e 'ngoe le e' ngoe ka mokhoa o sireletsehileng nakong ea ts'ebetso ea etching, ho felisa tlhokahalo ea manonyeletso a arohaneng. Ka lebaka leo, likarolo tsa bohlokoa tsa mokhabiso li ka hlophisoa ntle le ho tlosa lintlha tsa khokahano, ho etsa bonnete ba hore likarolo li lula li le boreleli ebile li hloekile.

-

Ho nepahala ho phahameng le ho Itloaetsa ka Metals ea HY: Likarolo tsa Likoloi tsa Leqephe le Tloaelehileng le Libese

E 'ngoe ea lihlahisoa tse ka sehloohong tse entsoeng ke HY Metals ke li-busbar tsa likoloi.

Li-busbars ke likarolo tsa bohlokoa tse fanang ka motlakase o sebetsang hantle le o ka tšeptjoang tsamaisong ea motlakase.

Ka mechini e tsoetseng pele le basebetsi ba nang le litsebo, HY Metals e fana ka litharollo tse entsoeng ka mokhoa o ikhethileng bakeng sa likarolo tsa likoloi tsa tšepe le libare tsa libese. Hore na ke moralo o rarahaneng kapa litlhoko tse ikhethang tsa sebopeho, lienjineri le litsebi tsa k'hamphani li na le boiphihlelo ba ho nts'etsapele le ho hlahisa lihlahisoa tse ikhethileng.

Ho feto-fetoha ha maemo hona ho lumella baetsi ba li-automaker ho aha lihlahisoa ho latela maemo a bona a nepahetseng, ho netefatsa hore li lekana hantle ebile li sebetsa hantle.