Tsebisa:

Ho etsoa ka tšepe ea pampirike karolo ea bohlokoa ea tlhahiso ea moetlo, 'me e' ngoe ea lits'ebetso tsa bohlokoa tse amehang ke ho tjheseletsa le ho kopanya.Ka boiphihlelo ba eona bo pharaletseng le bokhoni ba ho etsa lesela la tšepe, HY Metals e lula e leka ka matla ho ntlafatsa mekhoa ea eona ea ho tjheseletsa ho fana ka sephetho se phahameng.Ka poso ena ea blog, re hlahloba bohlokoa batjheseletsa le kopanoka mokhoa o nepahetseng oa ho etsa letlapa la tšepe, le kamoo HY Metals e phahamisang sekhahla ka letsete la eona la morao-rao ho mechini e mecha ea tjheseletsa.

Bohlokoa ba ho tjheseletsa le ho kopanya:

Ho tjheseletsa le ho kopanya ho phetha karolo ya bohlokwa tlhahisong ya letlapa la tshepe kaha di netefatsa botshepehi ba sebopeho le tshebetso ya sehlahiswa sa ho qetela.Hore na ho kopanya likarolo tse ngata hammoho kapa ho theha likopano tse rarahaneng, ho tjheseletsa ka nepo ke senotlolo sa ho fihlela sephetho se lakatsehang.Welding ha e fane feela ka matla le ho tšoarella, empa hape e tiisa hore sehlahisoa sa ho qetela se kopana le litlhaloso tse hlokahalang.

Boitlamo ba HY Metals ho Boleng:

Ka lifeme tse 'ne tsa tšepe le mabenkele a mane a CNC, HY Metals e se e le moetapele indastering.Boiphihlelo ba bona ba lilemo tse 13, mochini o pharalletseng le sehlopha sa basebetsi ba 350 ba koetlisitsoeng haholo li ba etsa tharollo ea mantlha bakeng sa hau.ho etsa lesela la tšepelitlhoko.Boitlamo ba HY Metals ho boleng bo bonahala boitekong ba bona bo tsoelang pele ba ho ntlafatsa ts'ebetso ea ho cheselletsa le ho kopanya.

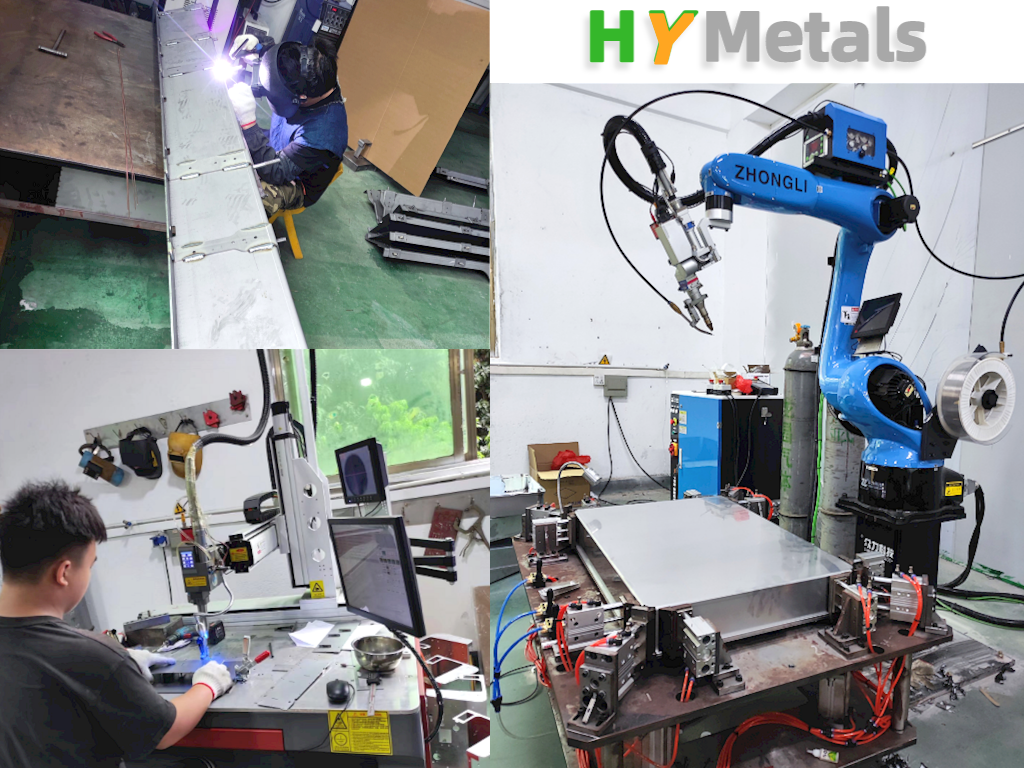

Matsete a macha a mochini oa welding:

Ho ntlafatsa bokhoni ba eona le ho feta, HY Metals e sa tsoa reka metjhini e mecha ea ho cheselletsa.Tsena li kenyelletsa liroboto tse tjheseletsang le metjhini e tjheseletsang e eketsang lebelo le ho nepahala ha tjheseletsa.Mechini ena e etsa bonnete ba hore welding e etsoa ka mokhoa o nepahetseng le ka bokhabane bo phahameng ka ho fetesisa, e leng se fellang ka lihlahisoa tsa tšepe tse ntle le tse nang le molumo o hlophisitsoeng hantle.

Melemo ea mochini o mocha oa welding:

Kenyelletso ea liroboto tse tjheseletsang le metjhini e tjheseletsang e fetotse tshebetso ya ho tjheseletsa ho HY Metals.Mechine ena e na le ho nepahala le lebelo le holimo, tse ka potlakisang tlhahiso le ho eketsa tlhahiso.Mechini ea welding e ikemetseng e tlosa kotsi ea phoso ea motho, ha liroboto tsa welding li ka etsa mesebetsi e rarahaneng ea ho tjheseletsa ka nepo e hlakileng.Tsoelo-pele ena ea theknoloji ea ho tjheseletsa e nolofalelitse HY Metals ho fa bareki lihlahisoa tsa boleng bo holimo - ka ponahalo le ts'ebetso.

Tsebo ea HY Metal:

Hape le mechini ea morao-rao ea ho cheselletsa, HY Metals e ithorisa ka botsebi ba li-welders tsa eona le ho nepahala ho holimo ha mechini ea eona.Litsebi tse nang le litsebo le lisebelisoa tsa morao-rao lia kopana ho etsa bonnete ba hore mosebetsi o mong le o mong oa ho cheseletsa o etsoa ka mokhoa o phethahetseng.HY Metals e ikarola tlholisanong ka ho shebana le ho hira le ho koetlisa li-welders tse nang le tsebo le ho tsetela mecheng ea boleng.

Ka kakaretso:

Ho tjheseletsa le ho kopanya ke dithulaganyo tsa konokono mo letlhakoreng la tshipi mme HY Metals e lemoga botlhokwa jwa tsone.Ka ho tsetela thepa e ncha ea ho tjheseletsa, ho kenyelletsa le liroboto tsa ho tjheseletsa le metjhini e tjheseletsang e itirisang, HY Metals e fihletse dintlafatso tse kgolo mabapi le lebelo la welding, ho nepahala le boleng ka kakaretso.Ka boiphihlelo bo pharaletseng, bokhoni bo matla le boitlamo ba phetheho, HY Metals e tsoela pele ho khahlisa bareki ka lits'ebeletso tsa eona tse ikhethang tsa ho etsa lesela la tšepe.

Nako ea poso: Jul-21-2023