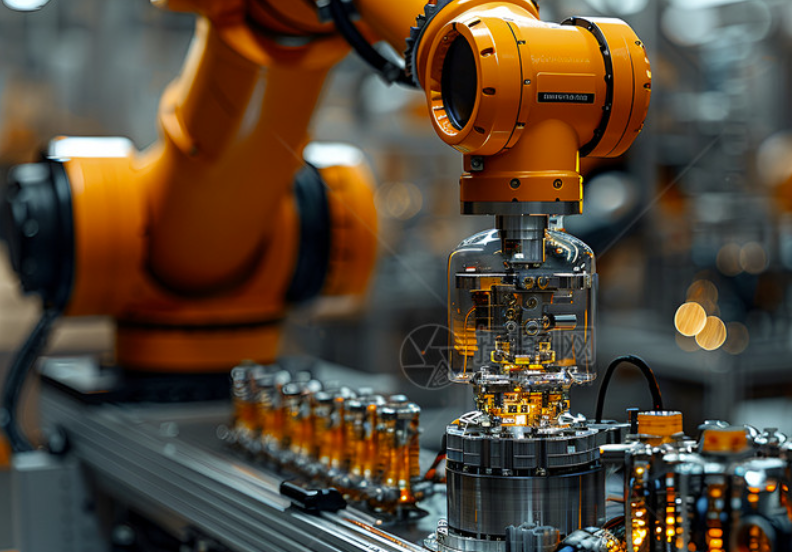

Theindasteri ea lirobotoe ka pele ho boqapi ba thekenoloji, e tsamaisang tsoelopele hoboiketsetso, bohlale ba maiketsetso, le tlhahiso e bohlale. Ho tloha ho liroboto tsa indasteri ho isa likoloing tse ikemetseng le liroboto tsa bongaka, tlhoko ealikarolo tsa boleng bo holimo, tse entsoeng ka nepoe phahame ho feta pele. Ho HY Metals, re sebetsa ka thata ho machining a nepahetseng le ho etsa tloaelo, re fana ka litharollo tse hlophisitsoeng ho fihlela litlhoko tse ikhethang tsa moralo le nts'etsopele ea liroboto. Hore na uprototyping roboto e ncha letsohokapa ho nyolla tlhahiso bakeng sa sistimi e tsoetseng pele ea ho iketsetsa, HY Metals ke molekane oa hau eo u mo tšepang bakeng saLikarolo tsa mochini oa CNC, ho etsa lesela la tšepe, le tse ling.

Karolo ea Likarolo tsa Precision ho Nts'etsopele ea Liroboto

Sistimi ea liroboto e itšetleha ka likarolo tse nepahetseng le tse tšepahalang haholo hore li sebetse hantle. Esita le ho kheloha ho honyenyane ka ho fetisisa litekanyong tsa karolo kapa karolong e ka holimo ho ka ama ts'ebetso ea tsamaiso ea liroboto. Mona ke moo HY Metals e ipabolang teng.Bokhoni ba rona ba ho etsa machining CNC, CNC milling, leCNC e fetohae etsa bonnete ba hore karolo e 'ngoe le e' ngoe eo re e hlahisang e kopana le mamello e thata e hlokahalang bakeng sa lisebelisoa tsa robotics.

Ka mohlala,matsoho a robotohloka manonyeletso a phahameng a nepahetseng le likhokahano ho fihlela metsamao e boreleli le e nepahetseng. Ka mokhoa o ts'oanang, li-sensor le litsamaiso tsa taolo li itšetlehile ka ho nepahalamatlo a entsoeng ka mechine le masakaho etsa bonnete ba tlhophiso e nepahetseng le tshebetso. Ka lisebelisoa tsa rona tsa morao-rao le baenjiniere ba nang le boiphihlelo,HY Metals e fana ka likarolo tse fihlelang litekanyetso tsena tse nepahetseng, e thusa lik'hamphani tsa liroboto ho etsa hore meralo ea bona e phele.

Bokhoni ba rona bakeng sa Prototyping ea Robotics le Tlhahiso

Ho HY Metals, re utloisisa seonts'etsopele ea lirobotohangata e kenyelletsa ho pheta-phetaprototypingletlhahiso ea lihlopha tse nyane. Mekhoa ea rona ea tlhahiso e feto-fetohang e etselitsoe ho tšehetsa litlhoko tsena,ho fana ka nako e potlakileng ea ho fetohalelitharollo tse bolokang chelete.

1. Mechine ea CNC bakeng sa Likaroloana tsa Robotics

Tsa ronaLitšebeletso tsa mochini oa CNCli loketse ho hlahisa li-geometri tse rarahaneng le likarolo tse mamellang ka thata, joalo ka:

- Manonyeletso a Robotic le Actuators:Likarolo tse entsoeng ka mokhoa o nepahetsengtse netefatsang motsamao o bonolo le o nepahetseng.

- Matlo a Sensor: Libaka tse tloahelehilengtse sireletsang lisebelisoa tsa elektronike tse hlokolosi ha li ntse li boloka tsamaiso e nepahetseng.

- Lisebelisoa tsa ho qetela:Lisebelisoa tse khethehileng le li-gripper tse etselitsoeng mesebetsi e itseng, joalo ka ho kha, ho cheselletsa kapa ho kopanya.

Ho sebelisa e tsoetseng peleMechini ea li-multi-axis CNC,re ka etsa meralo e rarahaneng ka ho nepahala ho ikhethang, ho netefatsa hore karolo e 'ngoe le e' ngoe e fihlela litlhoko tsa ts'ebeliso ea hau ea liroboto.

2. Custom Sheet Metal Fabrication

Ho tlatselletsoa hoMechine ea CNC, rea fanatloaelo e nepahetseng ea letlapa le entsoeng ka tšepebakeng sa lisebelisoa tsa robotics. Bokhoni ba rona bo kenyelletsa:

- Ho itšeha ka Laser:Bakeng sa ho theha libopeho tse nepahetseng le tse rarahaneng ho tloha holetlapa la tšepe.

- Ho kheloha le ho theha:Ho hlahisa tse tšoarellang le tse bobebeliforeimi, masakana, lelikoaheloa.

- Ho hatakela le ho lla:Bakeng sa mesebetsi e phahameng kapa e pheta-phetoang, ho netefatsa botsitso le katleho.

Litšebeletso tsena li bohlokoa haholo bakeng sa ho theha moralodikarolo, joalo kachassis ea roboto, masakana a ntseng a hola, lelikoahelo tse sireletsang.

3. Ho Qetella Bokaholimo bakeng sa Ts'ebetso e Ntlafetseng

Qetello ea bokaholimo e bapala karolo ea bohlokoa ts'ebetsong le ts'ebetsong ea nako e telelelikarolo tsa liroboto. Ho HY Metals, re fana ka mefuta e mengata ea likhetho tsa ho qeta bokaholimo, ho kenyelletsa:

- Anodizing:Bakeng sa ho hanyetsa kutu e ntlafetseng le qetello e boreleli, e tšoarellang.

- Ho roala ka phofo:Ho eketsa lera le sireletsang le le bonahalang ho likarolo tsa tšepe.

- Ho hloekisoa le ho hloekisa motlakase:Bakeng sa likarolo tse hlokang sebaka se boreleli, se se nang burr.

Ts'ebetso tsena tsa ho phethela ha li ntlafatse ponahalo ea likarolo tsa hau feela empa hape li ntlafatsa ts'ebetso ea tsona le bophelo bo bolelele ba ho batlalisebelisoa tsa robotics.

Hobaneng o Khetha HY Metals bakeng sa Nts'etsopele ea Liroboto?

Ha ho tluoa tabeng ea lirobotomoralo le ntshetsopele, ho sebelisana le k'hamphani e nepahetseng ea tlhahiso ho ka etsa phapang eohle. Ke ka lebaka lena HY Metals e leng khetho e nepahetseng:

1. Tsebo ea Tlhahiso e Phahameng ea Precision

Likarolo tsa liroboto li hloka ho nepahala ho phahameng ho netefatsa ts'ebetso e nepahetseng. Ka boiphihlelo ba lilemo kaho sebetsa ka nepoleho etsa moetlo, HY Metalse na le boiphihlelo ba ho fana ka likarolo tse fihlelang litlhoko tse batloang haholo.

2. Litšebeletso tsa Prototyping tse potlakileng

Re utloisisa hore nako e bohlokoa haholonts'etsopele ea liroboto. Tsa ronaprototyping e potlakilenglits'ebeletso li u lumella ho etsa liteko kapele le ho ntlafatsa meralo ea hau, ho potlakisa nako ea hau ea ho ea 'marakeng.

3. Bokhoni ba Tlhahiso ea Batch e Nyane

Merero e mengata ea liroboto e kenyelletsa tlhahiso ea li-batch tse nyane, leHY Metalse hlomeletsoe hantle ho sebetsana le litaelo tsena. Mekhoa ea rona ea tlhahiso e feto-fetohang e netefatsa hore u fumana likarolo tseo u li hlokang, ha u li hloka, ntle le litšenyehelo tse phahameng tse amanang le tlhahiso e kholo.

4. Comprehensive End-to-End Solutions

Ho tlohaMechine ea CNCleho etsa lesela la tšepe to top finishinglekopano, HY Metals e fana ka mefuta e mengata ea lits'ebeletso ho ts'ehetsants'etsopele ea lirobotolitlhoko. Sena se nolofatsa ketane ea phepelo ea hau mme se netefatsa boleng bo ts'oanang ho likarolo tsohle.

Lisebelisoa tsa 'Nete tsa Lefatše tsa Litšebeletso tsa HY Metals' ho Robotics

Boitseanape ba rona hoho sebetsa ka nepoleho etsa moetloe thusitse bareki ba bangata indastering ea liroboto ho fihlela sepheo sa bona. Mehlala e seng mekae ke ena:

- Liroboto tsa indasteri:Re hlahisitseLikarolo tsa tšepe tse entsoeng ka mochini oa CNCbakeng sa matsoho a liroboto a sebelisoang mehala ea kopano ea likoloi, ho netefatsa ts'ebetso e nepahetseng le e tšepahalang.

- Liroboto tsa Bongaka:Tsa ronatloaelo ea ho etsa lesela la tšepelits'ebeletso li ne li sebelisetsoa ho etsa liphaello tse bobebe le tse tšoarellang bakeng sa liroboto tsa ho buoa.

- Likoloi tse ikemetseng:Re fane ka li-sensor le li-brackets tse nepahetseng haholo bakeng saprototypes koloi e ikemetseng, e nolofalletsang pokello ea lintlha tse nepahetseng le ho tsamaea.

Kopana le HY Metals bakeng sa Litlhoko tsa hau tsa ntlafatso ea liroboto

Ho HY Metals, re chesehela ho tšehetsa boqapi hoindasteri ea liroboto. Hore na uho hlahisa setšoantšo se sechakapa ho eketsa tlhahiso, lits'ebeletso tsa rona tsa mochini o nepahetseng le lits'ebeletso tsa tlhahiso ea moetlo li etselitsoe ho u thusa ho atleha.

Ka botsebi ba rona hoMechine ea CNC, ho etsa lesela la tšepe, letop finishing, re ka fana kalikarolo tsa boleng bo holimoo hloka ho tlisa meralo ea hau ea liroboto bophelong.

Ikopanye le rona kajeno ho ithuta haholoanyane ka hore na HY Metals e ka ts'ehetsa merero ea hau ea ntlafatso ea liroboto joang le ho u thusa ho fihlela lipheo tsa hau ka nepo le ka ts'epo.

Ka ho khethaHY Metals, ha u fumane mofani oa thepa feela—u fumana molekane ea ikemiselitseng ho atleha lefatšeng le ntseng le tsoela pele ka potlako la liroboto. Ha re theheng bokamoso ba automation hammoho!

HY Litšepe fanasebaka se le senglits'ebeletso tsa tlhahiso ea moetlo ho kenyeletsaho etsa lesela la tšepeleMechine ea CNC,Lilemo tse 14 tsa boiphihleloleMehaho e 9 e nang le thepa ka botlalo.

Taolo ea boleng bo botle, phetoho e kgutshwane, puisano e kgolo.

Romella haoRFQ e nang lelitšoantšo tse qaqileng kajeno. Re tla u qotsa hanghang.

WeChat:na09260838

Bolella:+86 15815874097

Lengolo-tsoibila:susanx@hymetalproducts.com

Nako ea poso: Mar-13-2025