Tlhahiso ea tlhahiso

Sebakeng sa kajeno sa tlhahiso e potlakileng, ho na le tlhokahalo e ntseng e eketseha eaka potlako, likarolo tse nepahetseng tsa CNC tse entsoeng ka mochine.Ts'ebetso ena ea tlhahiso e fana ka ho nepahala ho ke keng ha bapisoa, ts'ebetso le botsitso, e etsa hore e be e loketseng liindasteri tse fapaneng ho kenyeletsoa.sefofane, koloiletsa bongaka.

Leha ho le joalo, mokhoa oa ho hlahisa likarolo tsena tse rarahaneng ha o na mathata.

Sehloohong sena, re tla hlahloba mathata a kopaneng le lintlha tse lokelang ho nahanoa ha ho etsoa tlhahisoho nepahala ka potlako likarolo tsa mochini oa CNC.

1.Ho rarahana le ho nahana ka moralo

Ho rarahana ha moralo ho bapala karolo ea bohlokoa tlhahisong ea likarolo tse entsoeng ka mochini oa CNC.Li-geometri tse rarahaneng, mamello e tiileng le metsamao ea li-axis tse ngata li hloka moralo o hlokolosi le boiphihlelo.Ho bohlokoa ho etsa bonnete ba hore moralo o ntlafalitsoe bakeng sa tlhahiso ho tloha methating ea pele.

Tšebelisano lipakeng tsa baenjiniere ba meralo le baetsi ba mananeo ba CNC e thusa ho tseba liphephetso tse ka bang teng tsa moralo pele ho nako, ho tsamaisa mekhoa ea mochini le ho fokotsa tieho e ka bang teng.

2.Khetho ea lintho tse bonahalang

Ntlha e ’ngoe ea bohlokoa e lokelang ho nahanoa kekhetho ea lintho tse bonahalang.Lisebelisoa tse fapaneng li tlisa mathata a fapaneng a ts'ebetso, 'me ho bohlokoa ho khetha thepa e nepahetseng bakeng sa ts'ebeliso e hlokahalang.Lisebelisoa tse ling, tse kang li-alloys tse sa keneleng mocheso kapa litšepe tse sa tloaelehang, ho thata ho li etsa mochine ka lebaka la ho thatafala ha tsona le ductility.Ho lekola bokhoni ba thepa, conductivity ea mocheso le boima ba 'mele ho bohlokoa ho qoba ho roala ha lisebelisoa, mathata a ho qetela kapa ho hloleha nakong ea mochini.

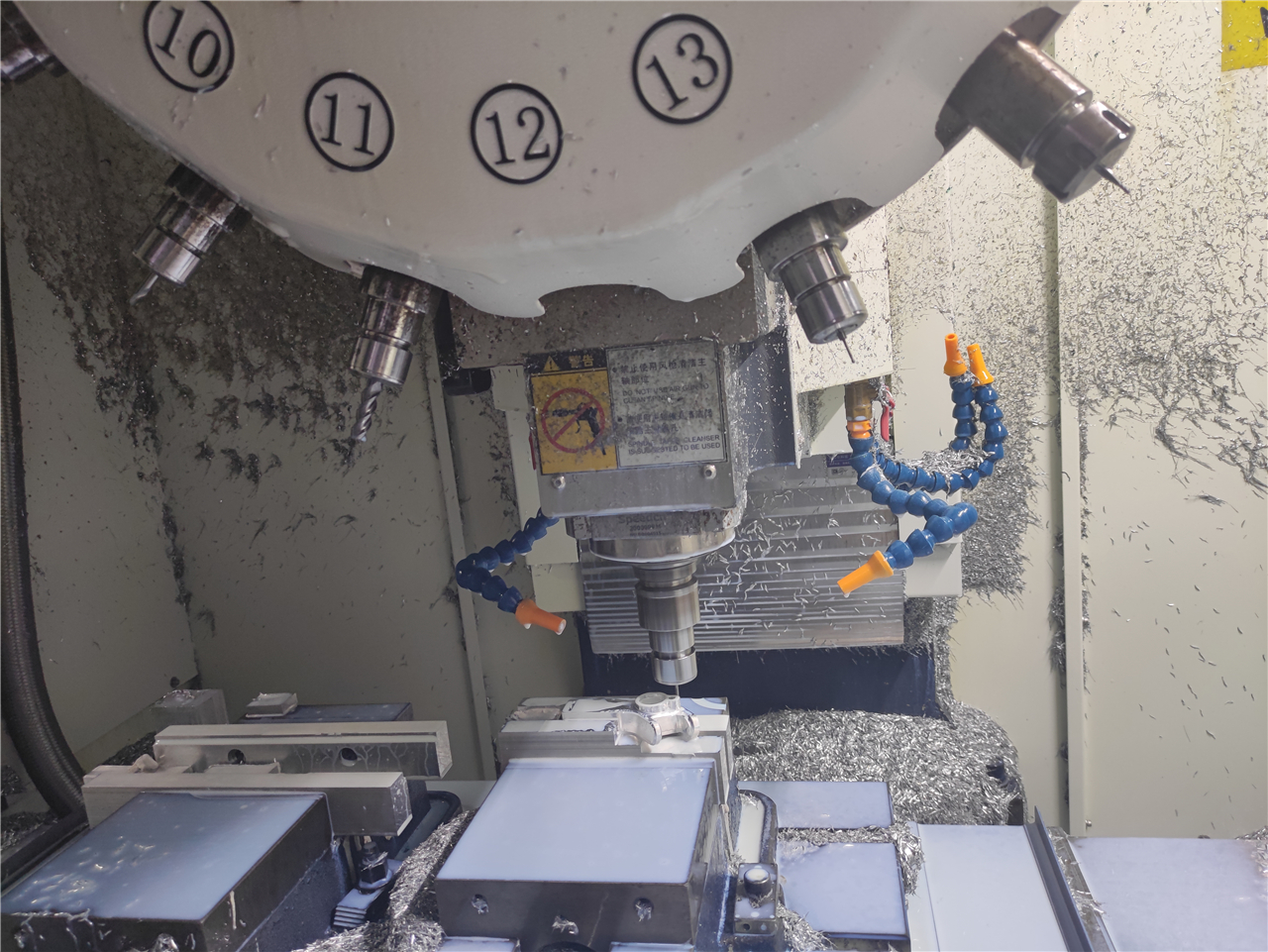

3.Bokhoni ba mochini le mananeo

Mokhoa o potlakileng, o nepahetseng oa likarolo tsa CNC o itšetlehile haholo ka bokhoni ba mochini oa CNC o sebelisitsoeng.Ho nepahala ha mochini, ho pheta-pheta le lebelo la spindle li ama haholo boleng ba sehlahisoa sa ho qetela.

Ho feta moo, ho bohlokoa ho ba lebaetsi ba mananeo ba CNC ba nang le boiphihlelo le ba nang le boiphihleloke mang ea ka ntlafatsang litsela tsa lisebelisoa, khetha li-parameter tse nepahetseng tsa ho itšeha, le ts'ebetso e rarahaneng ea machining.

4.Khetho ea lisebelisoa le ho ntlafatsa tsela ea lisebelisoa

Ho khetha sesebelisoa se nepahetseng sa ho itšeha ho bohlokoa ho fihlela ho nepahala ha mochini oa CNC.Lisebelisoa tsa lisebelisoa, li-geometry tsa lisebelisoa, liaparo, joalo-joalo li lokela ho nahanoa ho ipapisitse le thepa e ntseng e etsoa le sephetho se hlokahalang sa bokaholimo le mamello.

Ho feta moo, ho bohlokoa ho ntlafatsa mekhoa ea lisebelisoa ho fokotsa nako ea ho itšeha, ho fokotsa ho roala ha lisebelisoa, le ho netefatsa boleng bo tsitsitseng likarolong tse ngata.Ho sebelisa software e tsoetseng pele ea CAM ho ka thusa ho hlahisa litsela tse ntlafalitsoeng tsa lisebelisoa ho netefatsa ts'ebetso e sebetsang ea mochini.

5.Ho laola le ho hlahloba boleng

Ho boloka mehato e tiileng ea taolo ea boleng nakong eohle ea ts'ebetso ea tlhahiso ho bohlokoa ho likarolo tsa mochini oa CNC kapele le ka nepo.Ho sebelisa lisebelisoa tse tsoetseng pele tsa tlhahlobo tse kanghokahanya metjhini e lekanyang(CMM) le li-scanning probes li ka fana ka litekanyo tse nepahetseng tsa litekanyo le ho thusa ho lemoha mefokolo leha e le efe kapa ho kheloha ho tsoa ho litlhaloso.Lisebelisoa tsa ho sebetsa le lisebelisoa tsa ho hlahloba li lokela ho lekoa khafetsa le ho netefatsoa ho netefatsa tlhahiso e tsitsitseng ea boleng.

Ka kakaretso

Ho hlahisa likarolo tsa mochini oa CNC tse nepahetseng ka potlako ho tla le liphephetso tse fapaneng, ho kenyelletsa ho rarahana ha moralo, khetho ea thepa, bokhoni ba mochini, lisebelisoa le taolo ea boleng.Ka ho rarolla mathata ana, bahlahisi ba ka ntlafatsa ts'ebetso le ho nepahala ha mesebetsi ea bona ea machining.

Tšebelisano pakeng tsa baenjiniere ba meralo, baetsi ba mananeo, basebetsi ba mechini le basebetsi ba taolo ea boleng e phetha karolo ea bohlokoa ho hlola mathata ana le ho hlahisa likarolo tse nepahetseng tsa boleng bo holimo ka katleho.Bokamoso ba ho sebetsa ka mokhoa o nepahetseng ka potlako oa CNC bo shebahala bo ts'epahatsa ha theknoloji le boitseanape li ntse li tsoela pele, ho fetola indasteri le ho bula menyetla e mecha ea tlhahiso.

Nako ea poso: Oct-31-2023